Vortex to Display Dry Bulk Handling Components

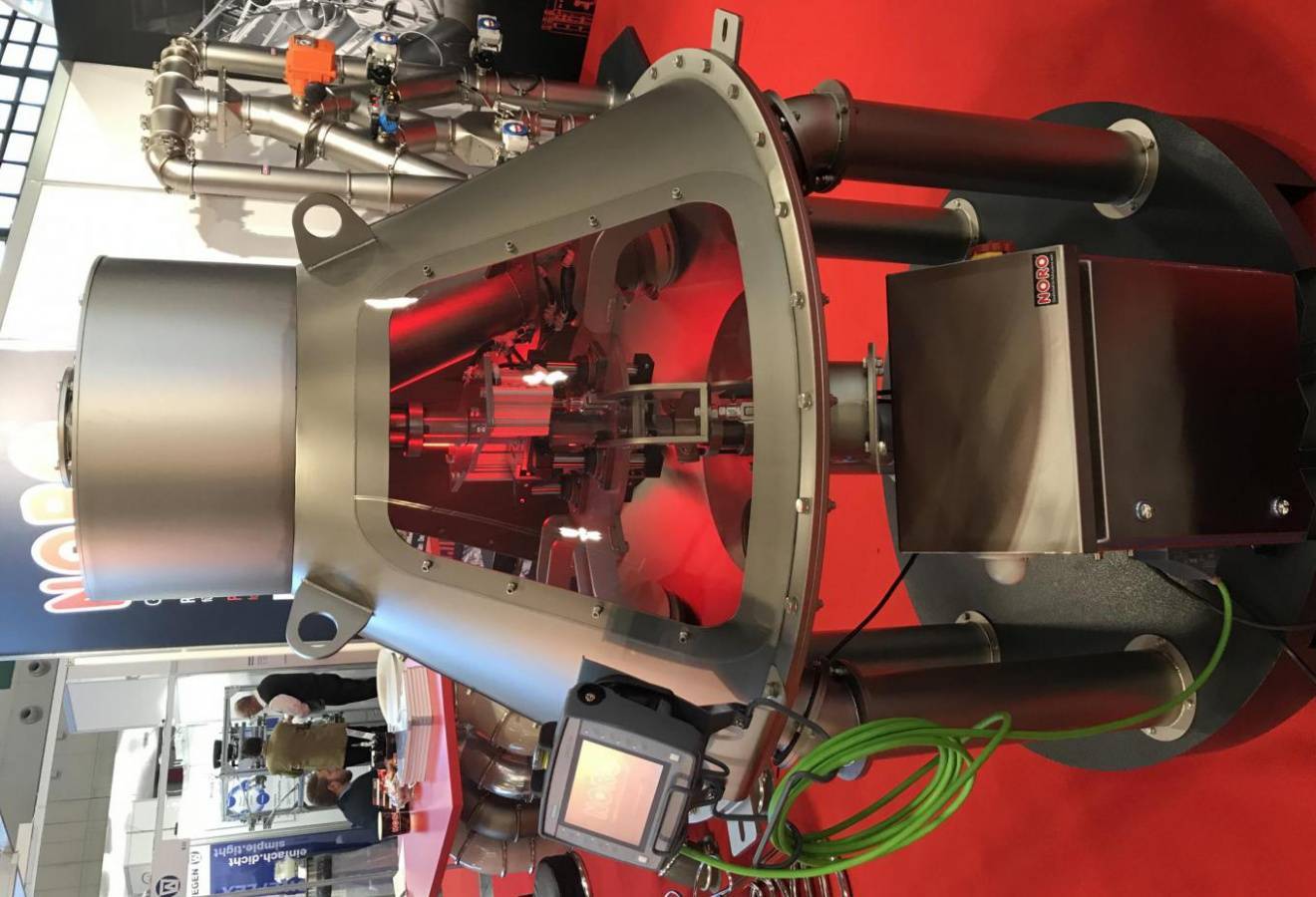

Powtech 2019 hall 4, stand 186 Vortex will display several products at Powtech 2019, Hall 4, Stand 186, 26-28 September, in Nürnberg, Germany.

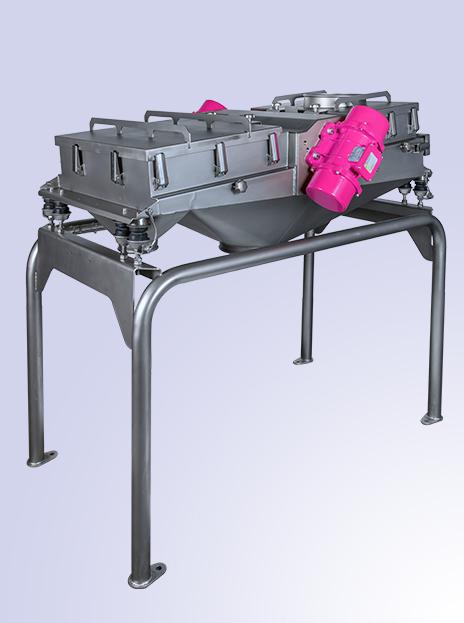

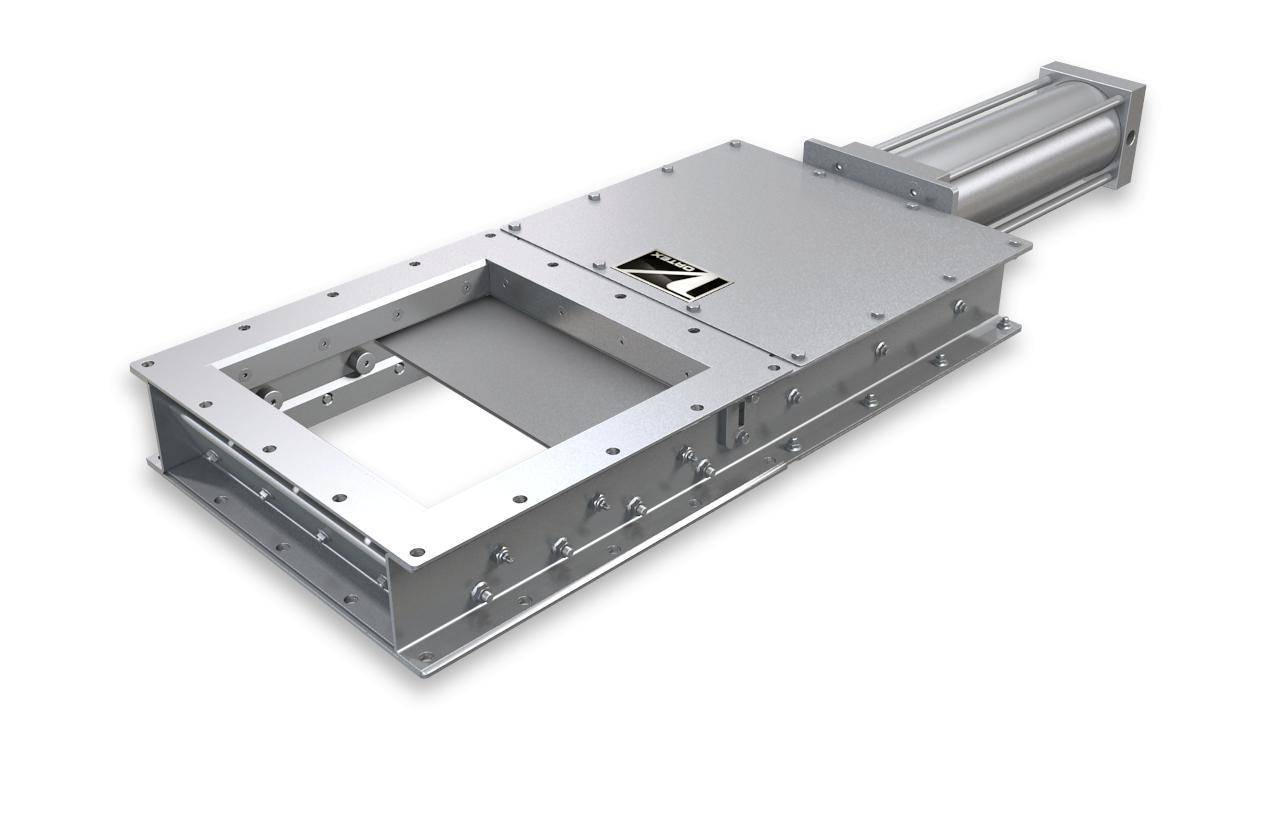

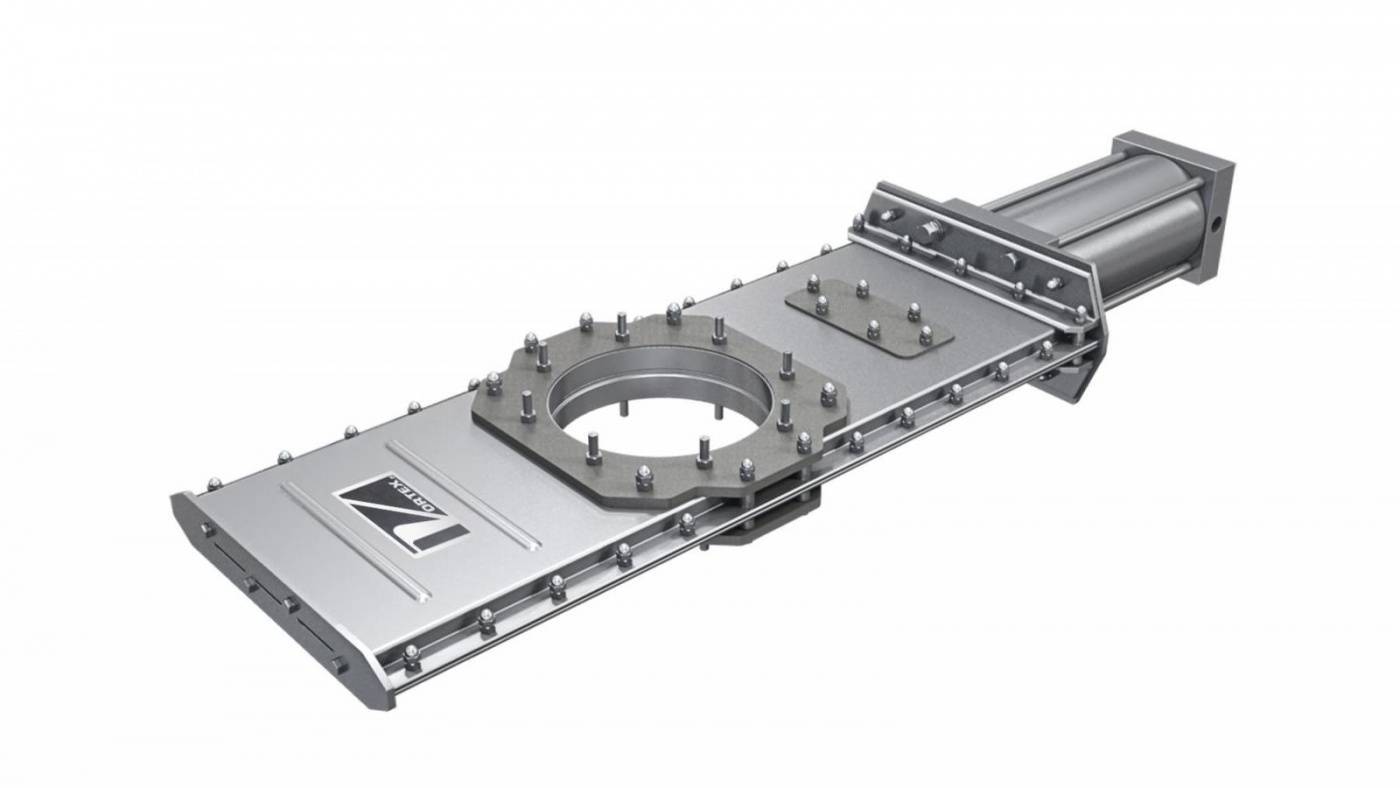

Vortex’s Titan Series slide gates and diverters are valves engineered for heavy duty material handling applications that pose additional abrasion or wear issues to the valve. Some of the materials handled with Vortex Titan valves include alumina, bauxite, cement, clinker, coal, fly ash, frac sand, gravel, glass cullet, lime, limestone, metal powders, potash and sand.

The Titan TLD Diverter offers replaceable wear liners for added abrasion resistance and removable access panels for internal inspection, cleaning or maintenance. The Titan TSG Gate handles dry material in gravity flow applications where positive material shut-off and dust tight sealing is required. Vortex’s Aggregate Diverter has optional inlets, chute liners, and bucket liners that extend the life of the valve when handling abrasive