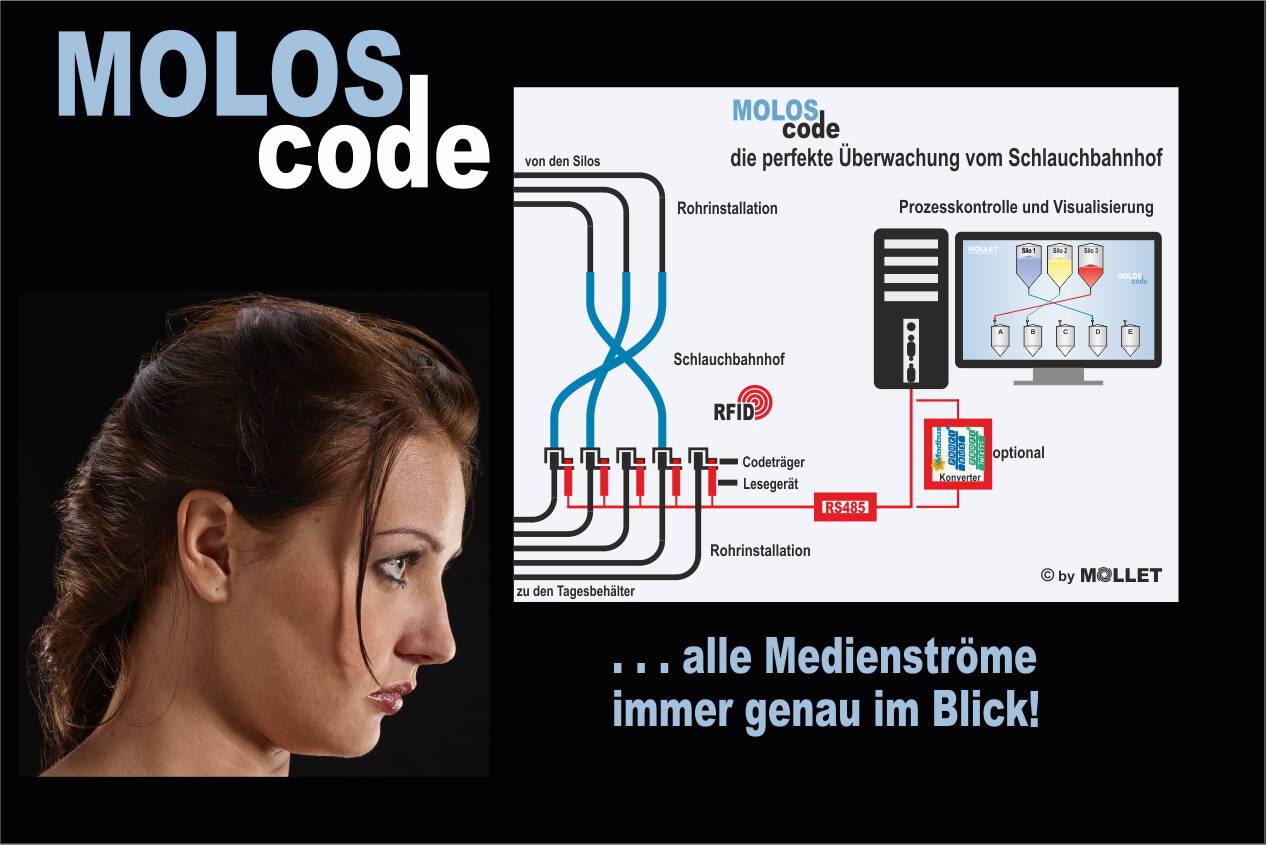

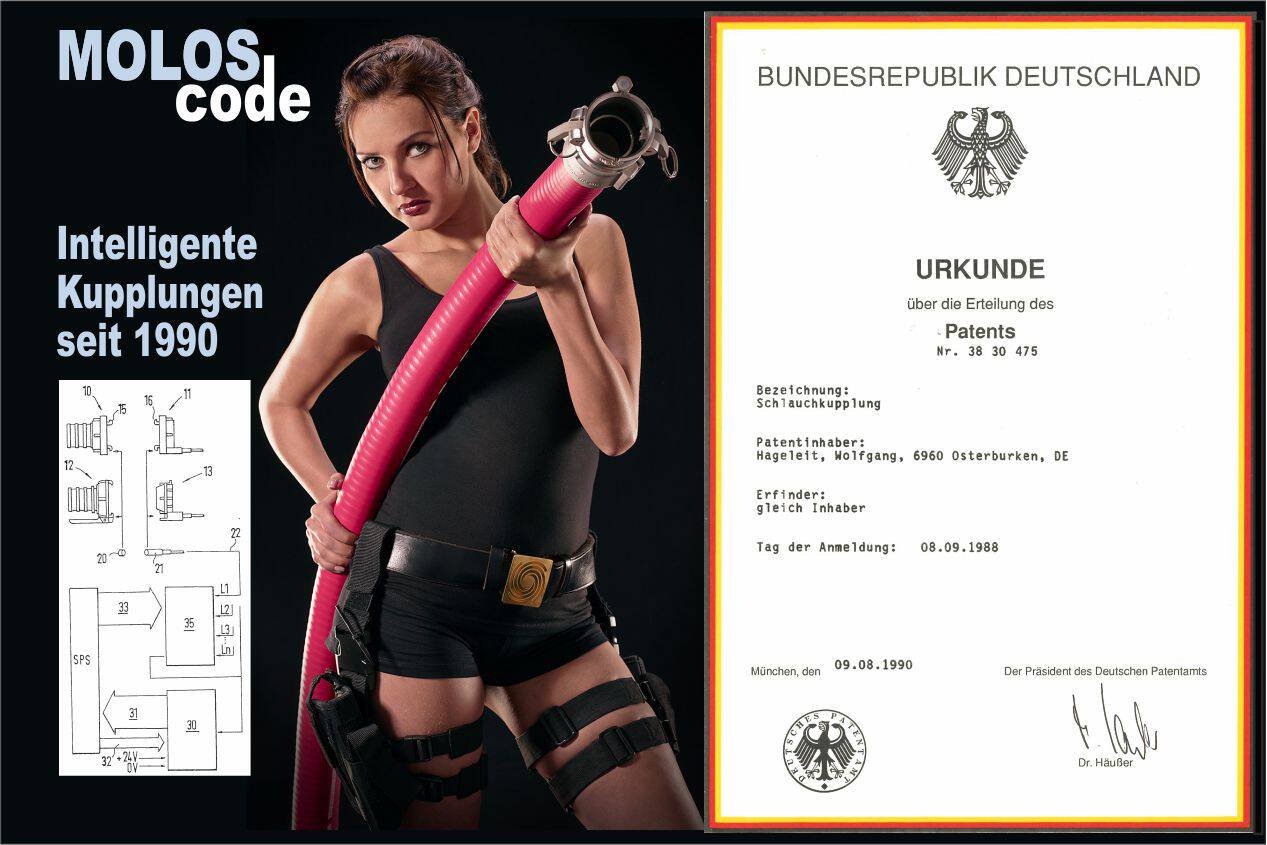

MOLLET is a producer of high-end devices for measurement and control systems. Our customers coming from many different industries such as pharmaceutical industry as well as construction industry appreciate especially our safety equipment for silos and bulk material facilities. Mollet meets customers’ highest requirements with the wide range of level control units for all kind of bulk solids. Another product line of Mollet is hose couplings with integrated limit switches or with electronic encoding systems. A stand alone silo-safe-system for fully-automated monitoring of the filling process for silos that have to be filled pneumatically by silo trailers completes the product range.

Established in 1983, Mollet extend its position in the world market very quickly. Today Mollet with its domestic and international sales partners supply quality control devices to many satisfied customers around the world.

The core competence of Mollet is explosion-proof in accordance with ATEX. Mollet became an expert for this topic. All devices of Mollet are available with a wide range of different ATEX approvals for hazardous areas with combustible gases and dust. Unique for this kind of level measurement units are the approvals for hybrid mixtures that mean inflammable gas and dust together in the air at the same time. These explosive mixtures are the most dangerous ones.

Categories

Safety - Safety regulations -

ATEXConveyors - Belt conveyors - Components -

Belt misalignment switchesConveyors - Pneumatic transport - Components, accessories -

Clamp couplingsConveyors - Pneumatic transport - Components, accessories -

Flange couplingsProcess control, instrumentation - Switches -

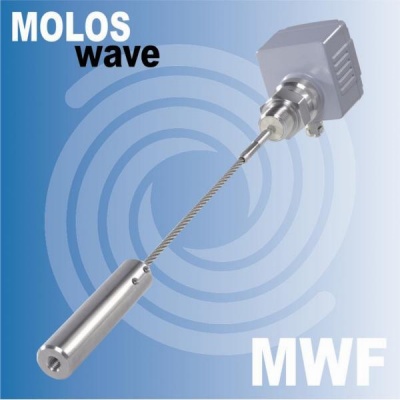

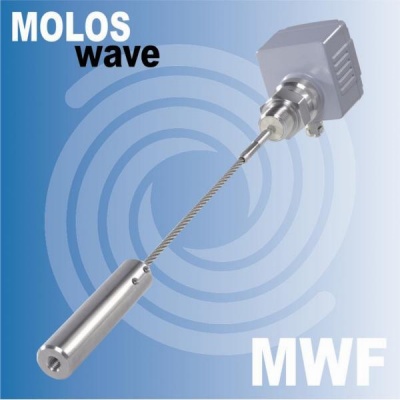

Pressure switchesProcess control, instrumentation - Meters, measurement - Level meters -

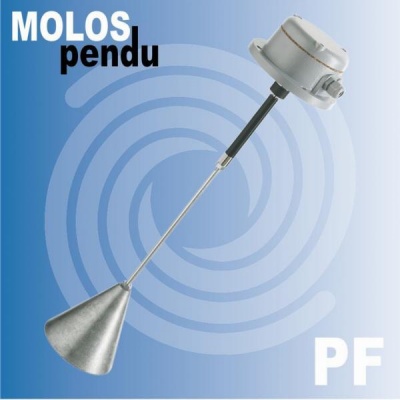

Radar level metersProcess control, instrumentation - Switches - Level switches -

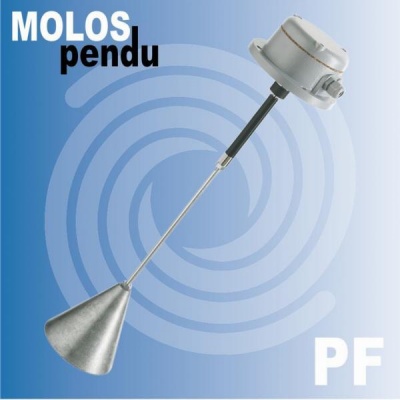

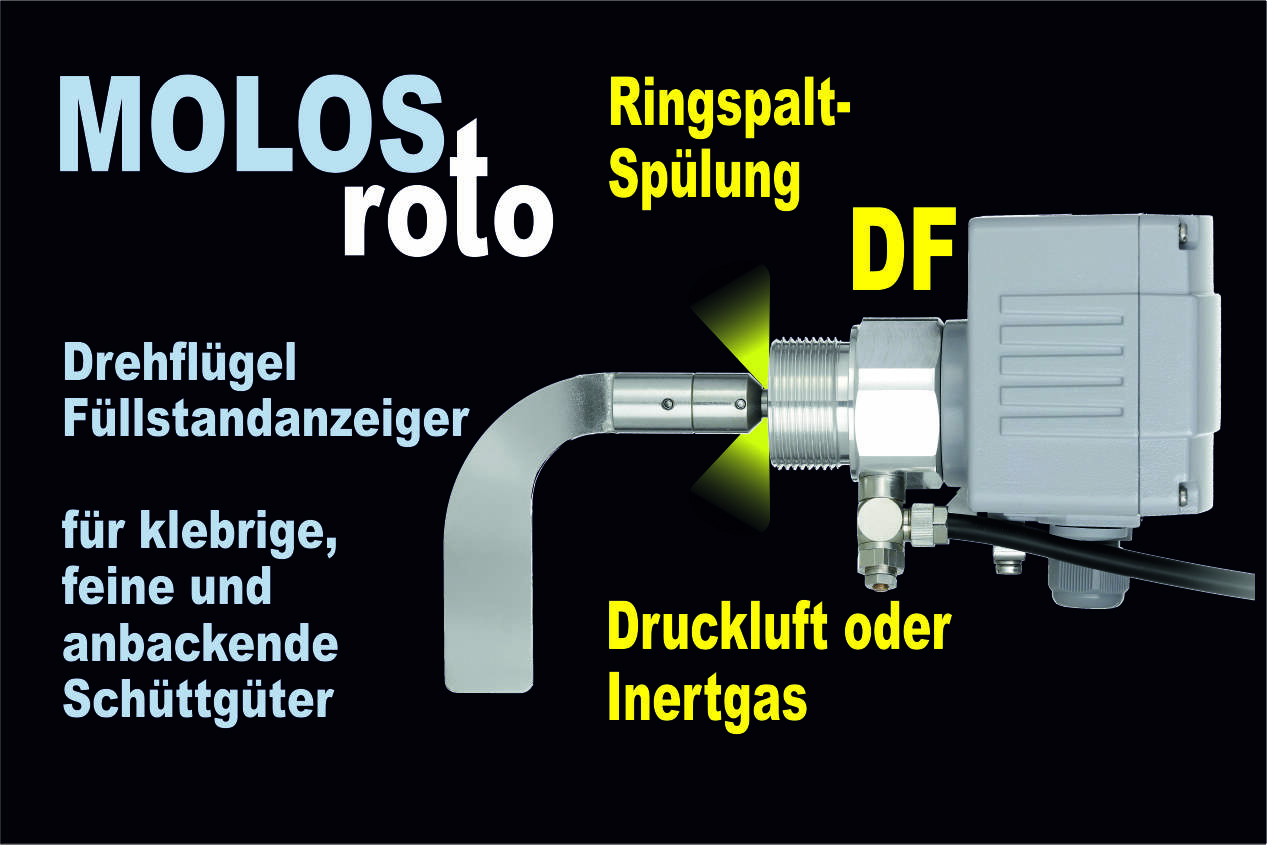

Rotating vane level switchesProcess control, instrumentation - Switches - Level switches -

Tuning fork level switchesComponents, accessories - Valves, slides, sluices - Valves -

Valves