Short course: Port and Terminal Operations for Bulk Cargoes

understand the issues surrounding the safe handling and storage of bulk materials in port terminals and at sea. Join the experts from the Wolfson Centre for Bulk Solids Handling Technology as they deliver this online course, written for anyone concerned about, who handles or is responsible for the safe transportation and storage of bulk materials, such as Stevedores, Operations supervisors, Port managers, Ships Masters, Port developers, Cargo superintendents, Equipment suppliers, Design consultants.

A short course to discuss real life issues and to determine best practice for future developments.

Some of the topics covered include:

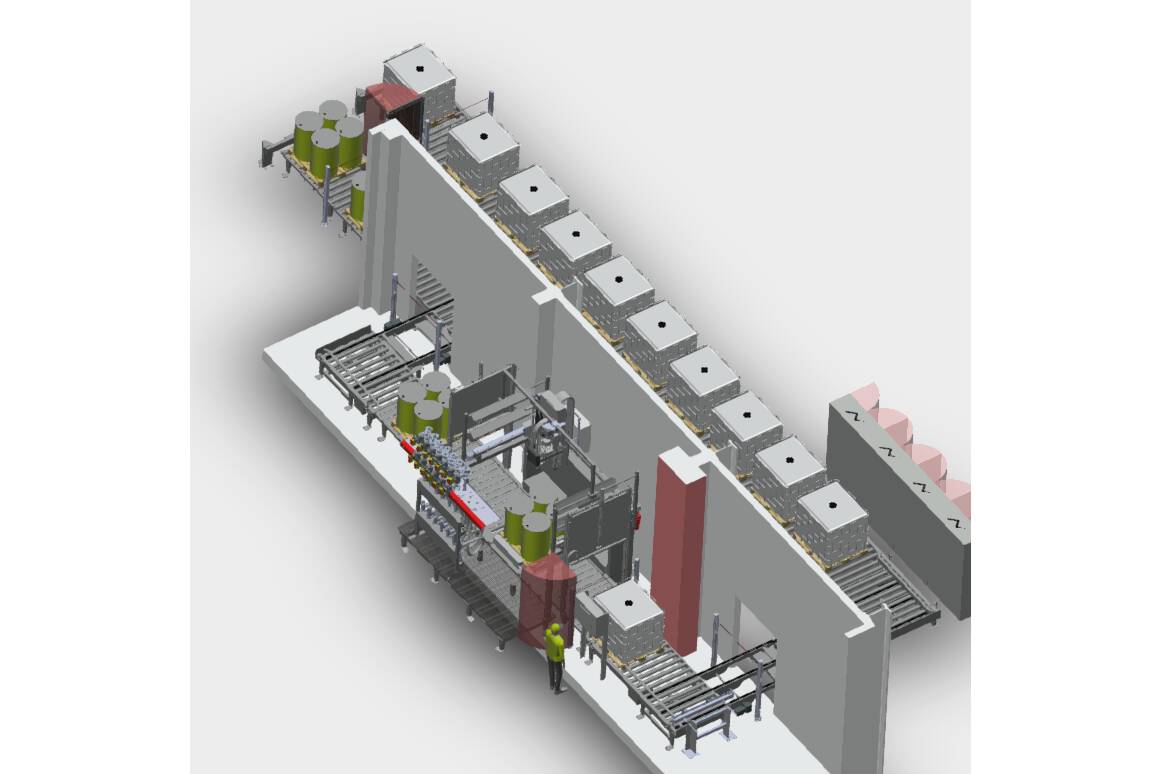

* Ship unloading technologies (Grabs vs CSUs, different CSU technologies)

* Conveying technologies (pneumatic vs belt)

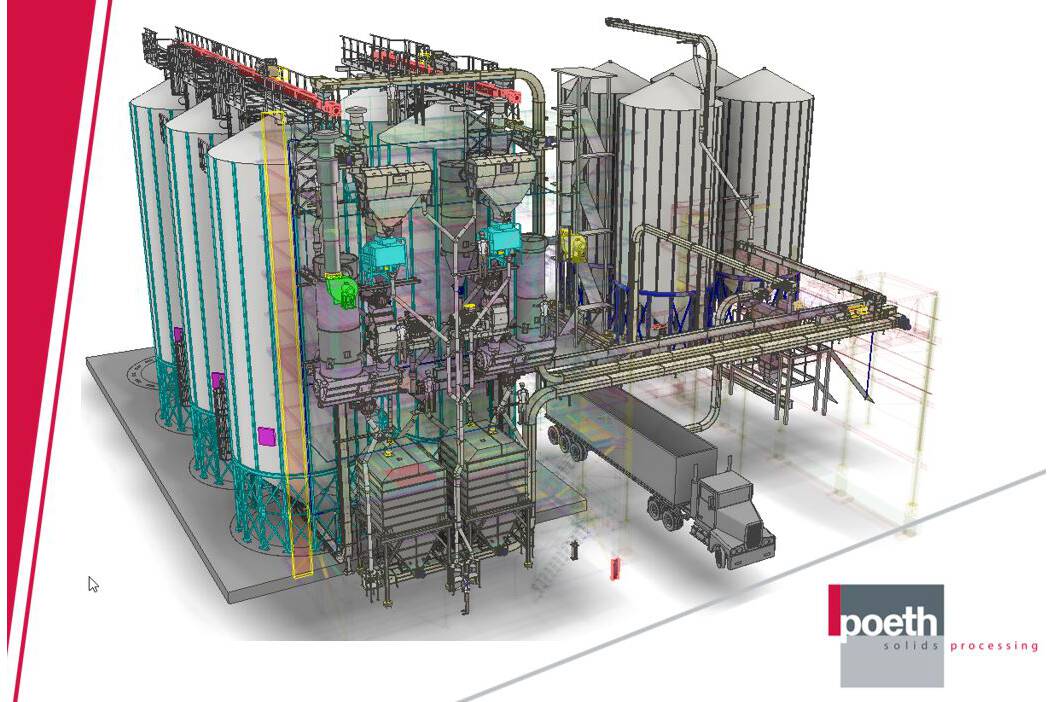

* Storage and discharge technologies (silos, flat stores, stacking etc)

* Loading/unloading control (weighing, controlling ship bending etc)

* Rail and road out-loading equipment and control

* Explosion and fire risks and management (ATEX, fire control and management)

* Mobile plant and safety

* Developments in