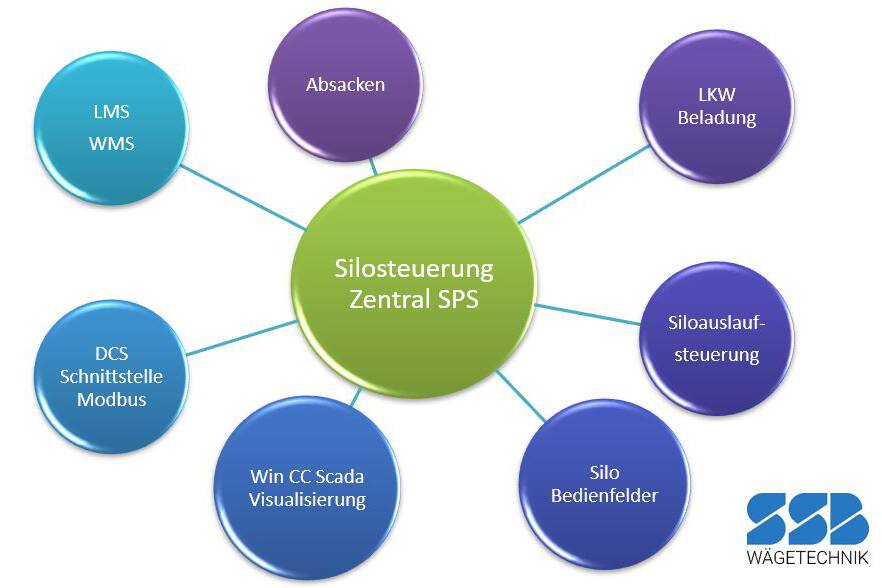

Silo Control and visualization

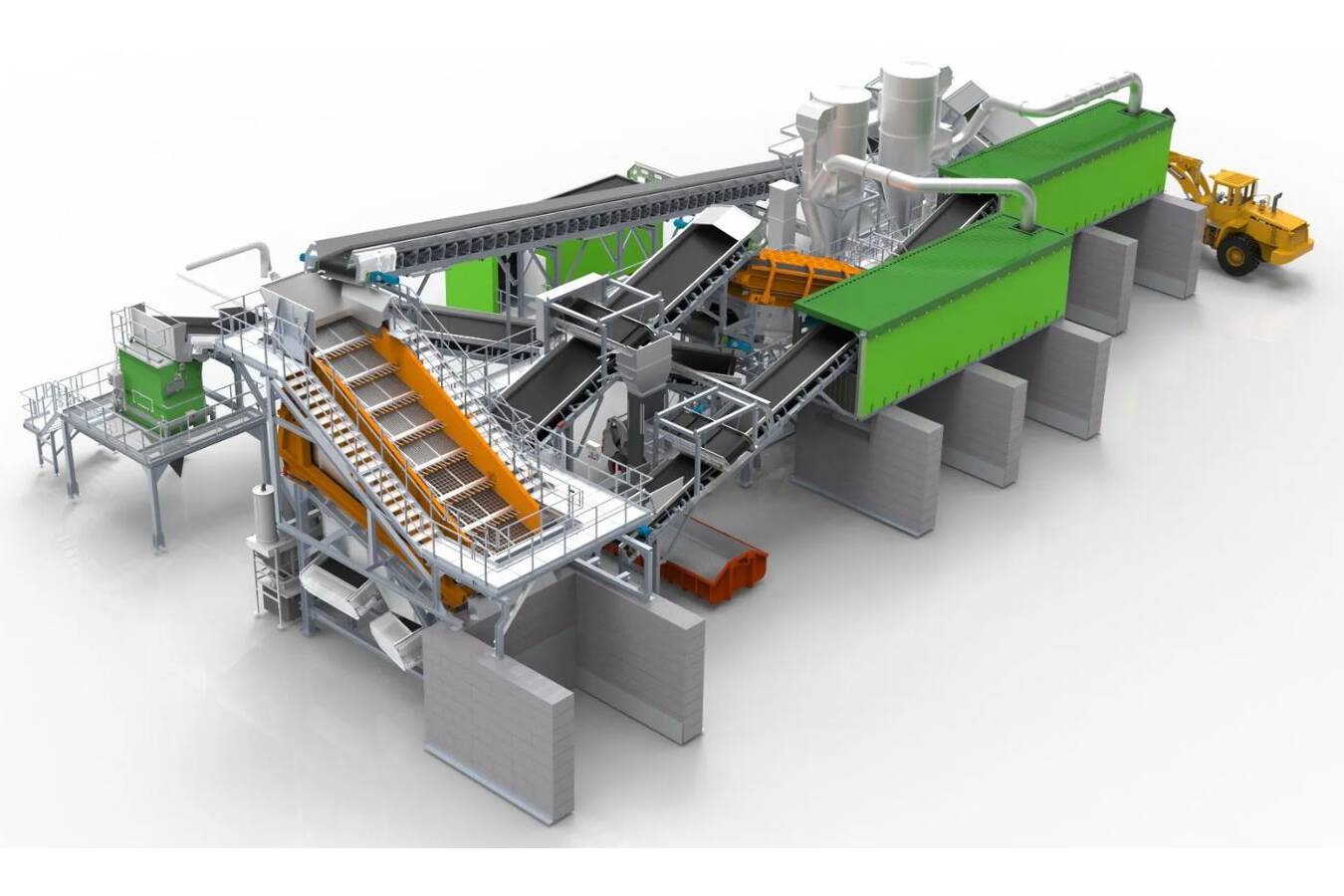

In the field of silo control and visualisation, we offer a wide range of solutions to independently manage and control your silo system. With our silo-control system, which can either be integrated into software tools such as SAP and ORACLE or tailored to your own database exchange, the management of your silo plant becomes more targeted, convenient and functional. When using a control system, the production processes from product receipt, order acceptance, silo discharge control, safety scanning, determination of filling variants (e.g. truck, big bag, FFS) and backtracking to the finished container can be precisely monitored and controlled. The WinCC software solution we offer helps you optimize the management of your plant and make it autonomous and user-friendly.

To make the control of your silo plant even more functional, we offer control systems with integration of the filling technology, visualization system and databases. In addition to process monitoring, our silo control systems also enable remote monitoring with worldwide access, linking with databases, connection of truck scales, and flexible