Screening machines with pneumatic vacuum cleaning for sorbitol

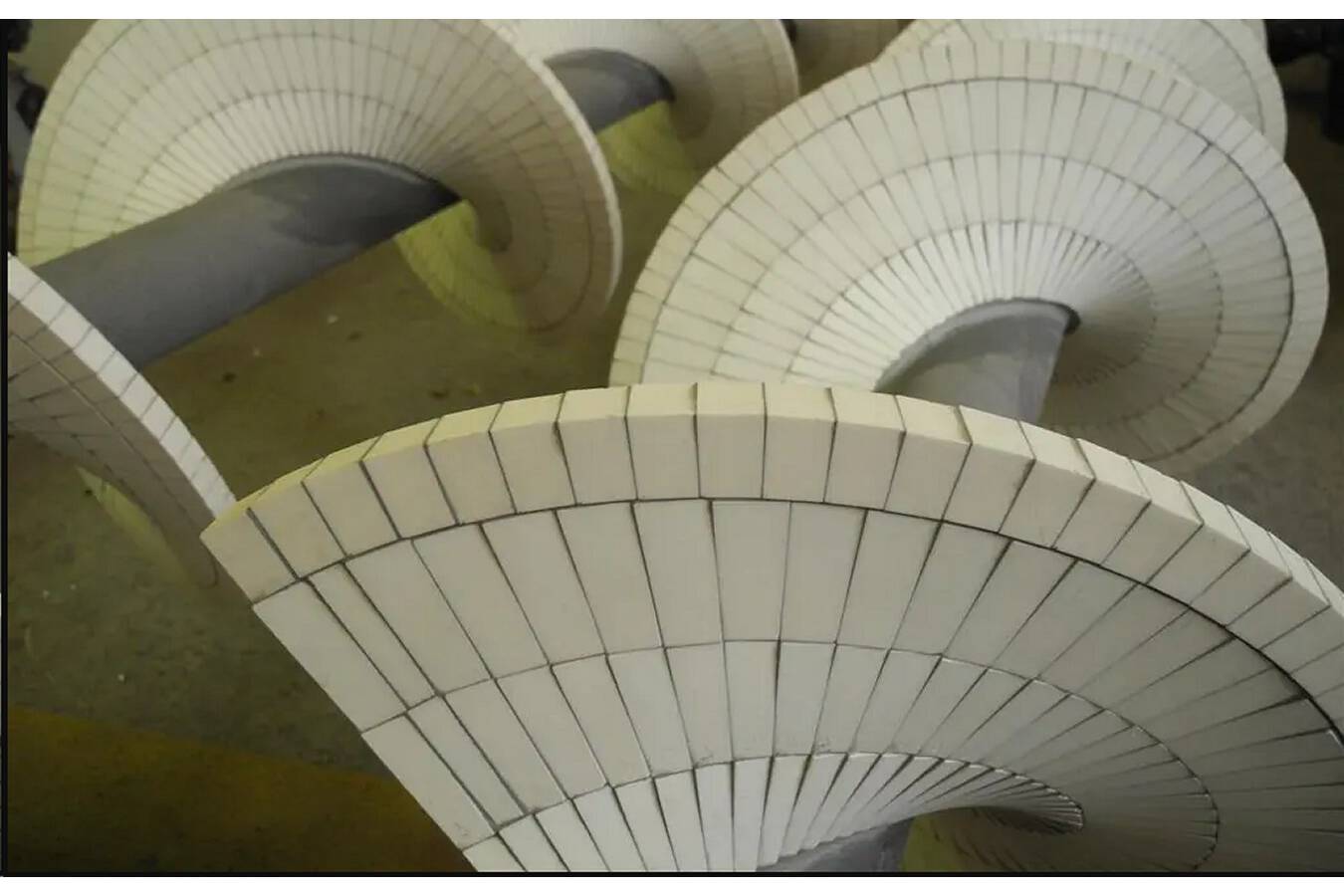

Four profitable RHEsono® vibrating screening machines equipped with pneumatic vacuum cleaning technology have been delivered to Shanghai, China. These machines are set to advance the sieving process for sorbitol, a widely used sugar substitute and food additive (E 420) in various industrially manufactured food products.

Each of the four RHEsono® sieving machines is equipped with three sieve decks and a remarkable processing capacity of 10 tons per hour. The sieving application involves sorbitol with three distinct particle size fractions: 1.25 mm, 0.5 mm, and 0.28 mm. Sorbitol, also known as food additive E 420, glucitol or hexanhexol, belongs to the group of sugar alcohols, making it a crucial ingredient in the food industry as a sugar substitute, carrier substance, and moisture retention agent.

The Challenge of Sieving Sorbitol

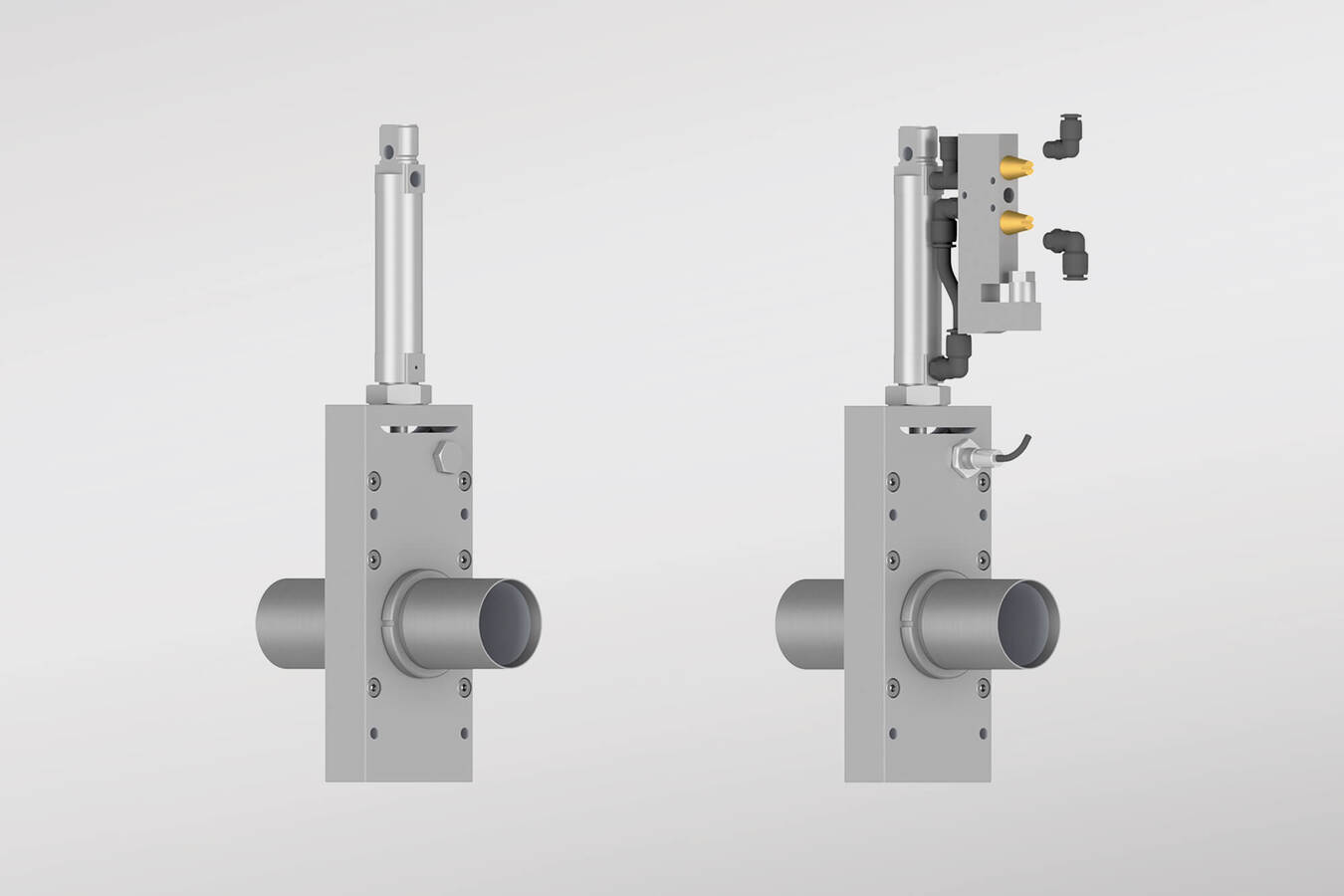

Sorbitol processing can be a challenging task due to its sticky nature even when it has low moisture levels. This characteristic can lead to sieving complications, including mesh clogging, which can negatively impact product quality. To address this issue, RHEWUM’s RHEsono®