Interview with SSB Wägetechnik from Easy Engineering Magazine

An insight into the industry and expectations for the coming year. What are the company’s main areas of activity?

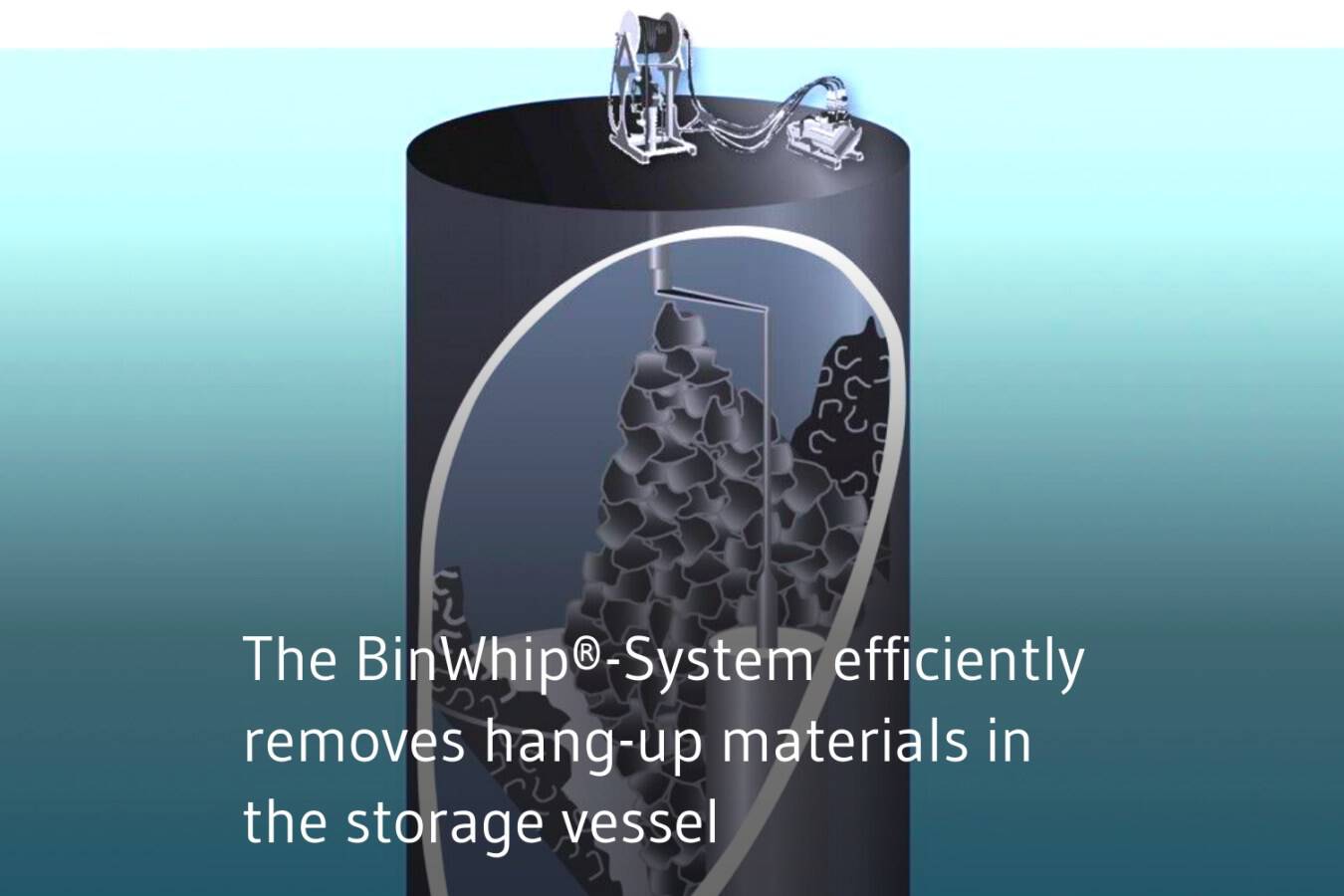

Weighing, bagging and control technology. Palletising technology/ palletising solutions. Complete systems, silo discharge, packaging machines, truck loading technology, plant engineering, silo control.

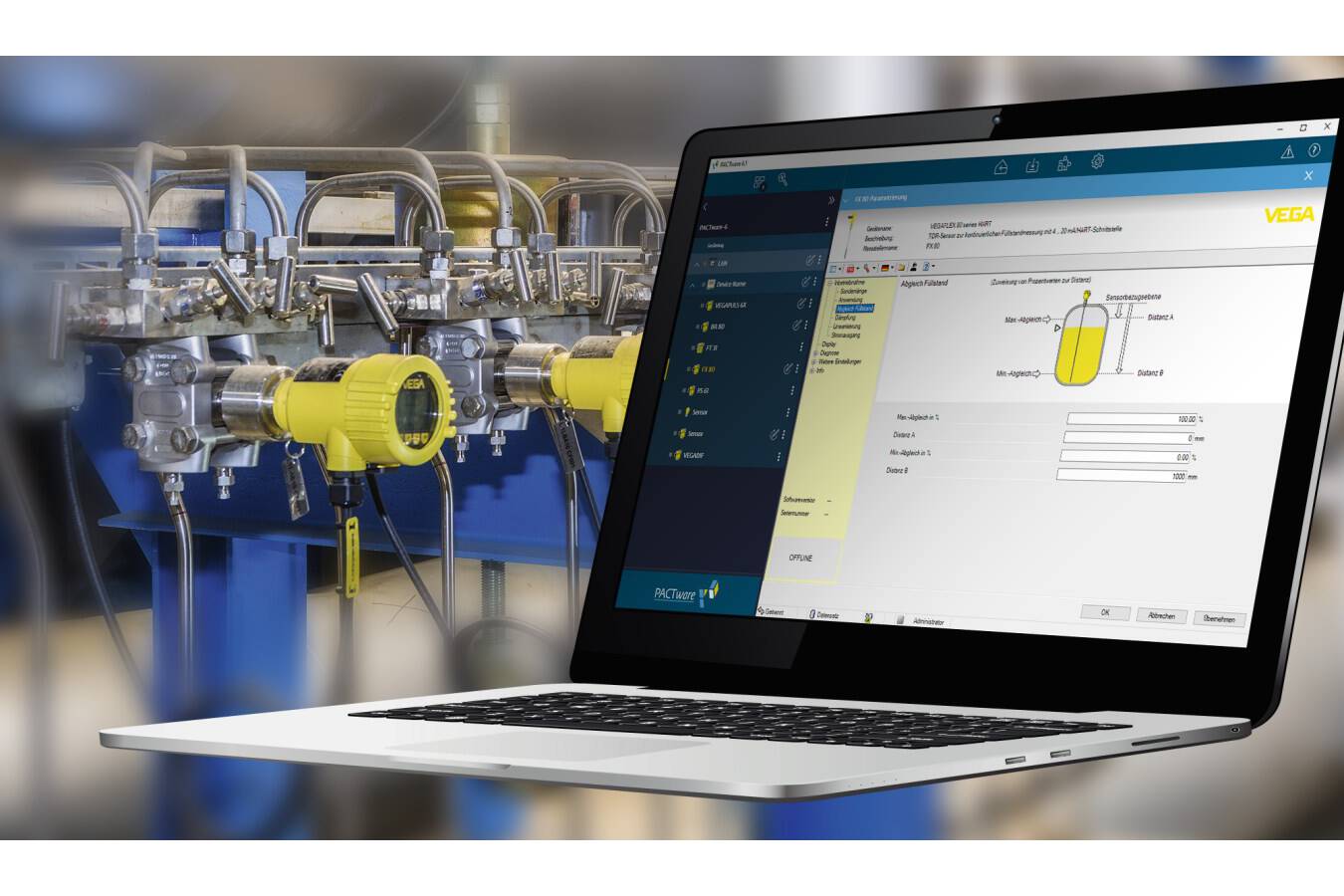

In addition: customer service, calibration preparation and calibration, spare parts service, weighing components.

We serve customers from all industries who need to pack their products (their bulk goods) for further processing and transport. The bulk industry has benefited from significant technological advances. Automated conveying and handling systems, sensor technologies and IoT applications have significantly improved the efficiency and accuracy of moving, processing, packaging and transporting bulk materials. Increased efficiency through machines: processes are taken over that human workers can no longer and no longer necessarily perform.