Positive feedback and gratitude from Gericke’s customers

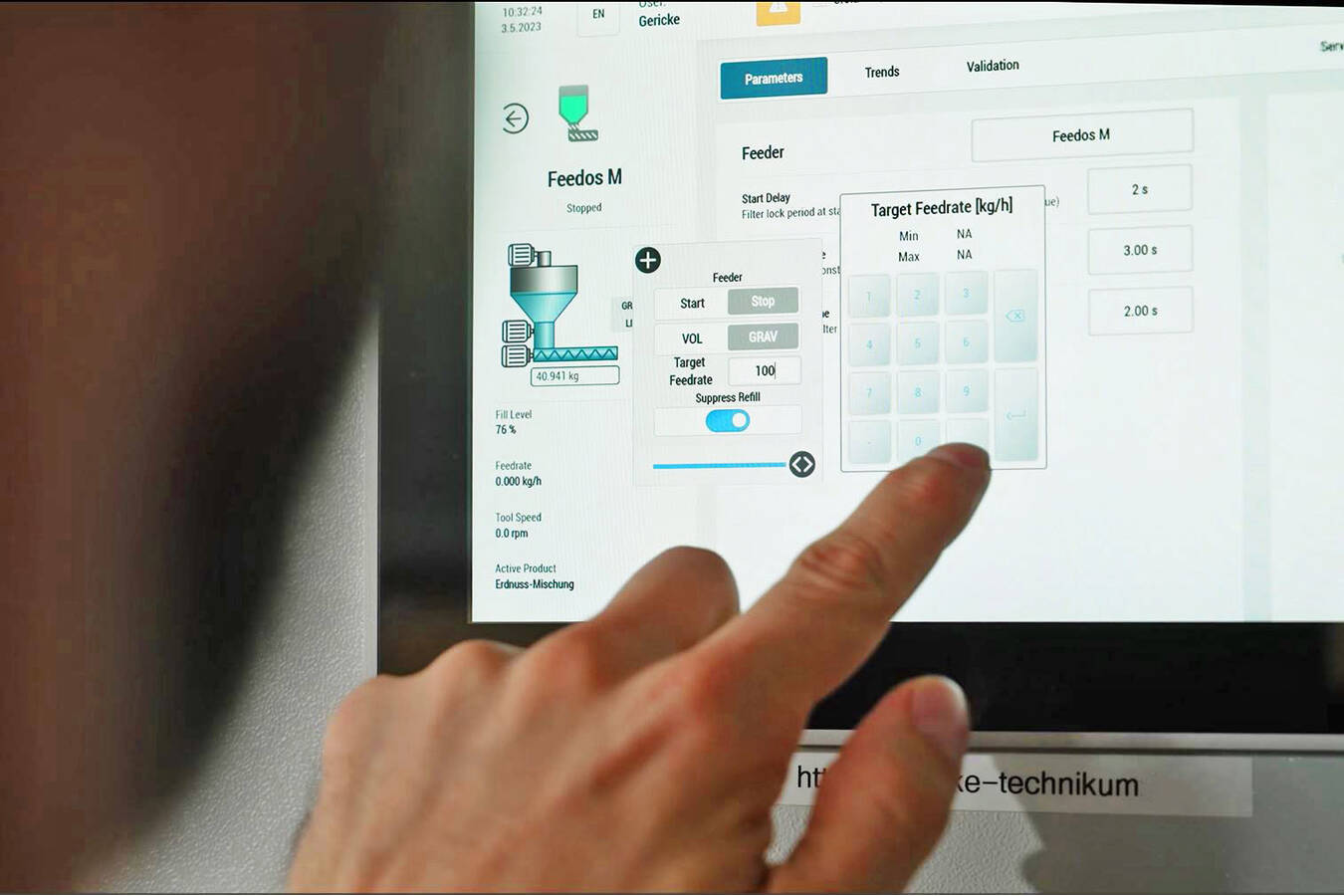

Gericke and Its Employees Garner Rave Reviews and Heartfelt Appreciation from Customers Gericke, a leading provider of innovative solutions in the bulk powder processing industry, is proud to announce an outpouring of positive feedback and expressions of gratitude from its valued customers. The exceptional dedication and professionalism displayed by Gericke’s employees have left a lasting impression on clients, reinforcing the company’s commitment to excellence and customer satisfaction.

Over the past months, Gericke has received numerous testimonials and messages of appreciation, highlighting the remarkable contributions made by its employees. Customers have praised the exceptional level of service, technical expertise, and collaborative approach demonstrated by Gericke’s staff members, leading to successful project outcomes and enhanced business performance.

One customer, Jos Hofland from Worley, described Gericke as a ‘well-oiled machine’. The feedback stated, “I hereby want to let you know how pleased I am with the way Marieke in particular