Fast and perfect sample preparation for spectroscopy

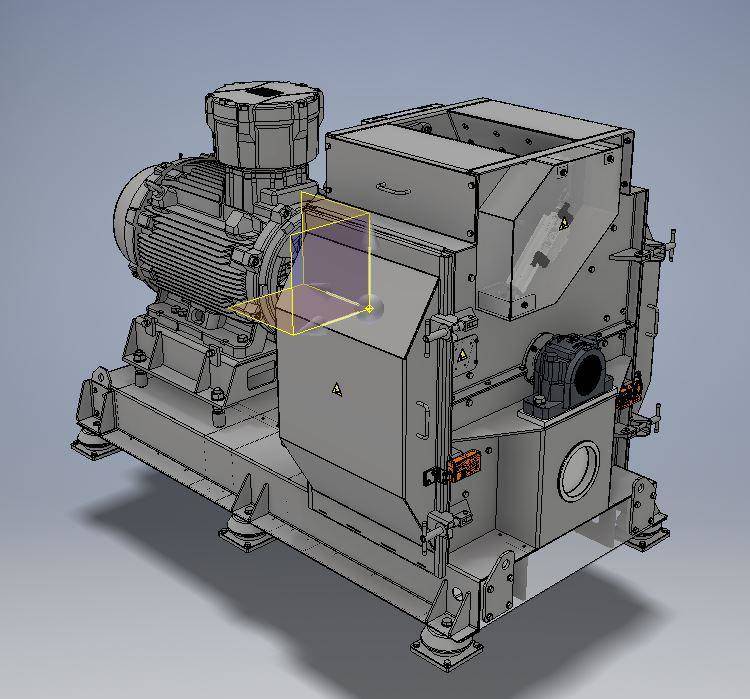

The Fritsch vibrating Cup Mill Pulverisette 9 offers many practical advantages in all areas in which hard, brittle and fibrous material must be ground extremely quick down to analytical fineness. She is indispensable for fast sample preparation, for example in spectroscopy preparation, ore and geology laboratories, mining and metallurgy, ceramics industry, agriculture and environment, infrared and X-ray fluorescence analysis.

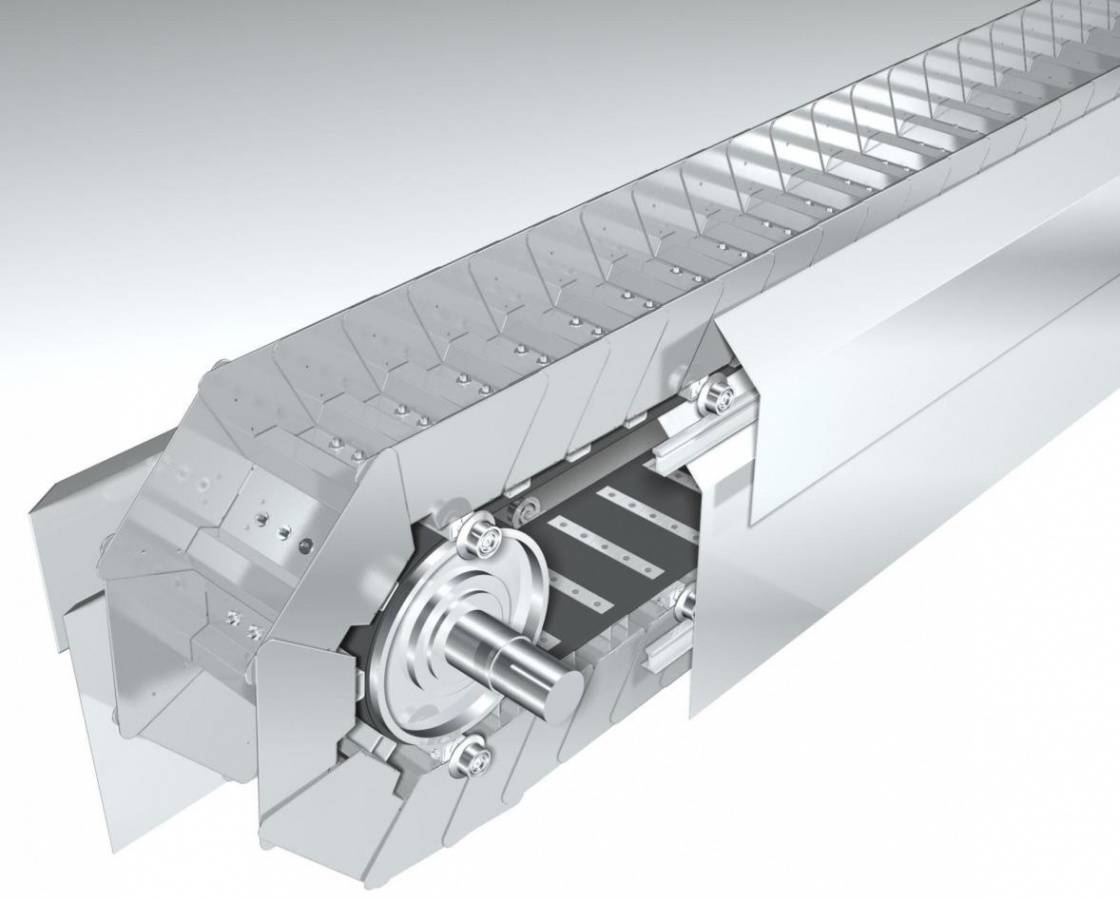

The Pulverisette 9 is very powerful, especially quiet, simple to operate, quick to clean and has a well-conceived drive concept and the grinding set is safe and easy to tension. For perfect, loss-free grinding results in extremely short grinding time.

Your advantages with the Vibrating Cup Mill Pulverisette 9

- High power with well-conceived drive concept

- Extra-fast grinding with up to 1500 rpm

- Grinding sets in 5 different materials and 3 different sizes from 50 ml to 250 ml

volume are available – for each application the suitable