Tracking System new and different PrimeTracker

Scrapetec presents successful a new tracking system against belt misalignment.

New to Scrapetec’s range of conveyor components is the PrimeTracker belt tracker, which eliminates problems associated with conveyor belt systems, including misalignment, abrasion, and belt damage.

“For optimum performance of a conveyor system, it is critical that the belt always runs straight on the conveyor, without sideways movement. Our new PrimeTracker belt tracker has been designed to automatically guide a conveyor belt back into the correct straight-line position, to prevent costly downtime and component replacement,” explained Thorsten Koth, sales and distribution for Scrapetec. “An advantage of the Scrapetec PrimeTracker is that it is operates in the idling position at all times, unless there is sideways movement of the belt. This system corrects misalignment immediately by guiding the belt back into the correct position, with no damage or abrasion to the belt or tracker. Perfect for reversible operation.

“This is unlike conventional belt trackers that slide over the belt surface causing possible abrasion and belt damage - rather than adopting free rotation. Conventional belt trackers, with tapered edges, never idle and are always in a braking mode.

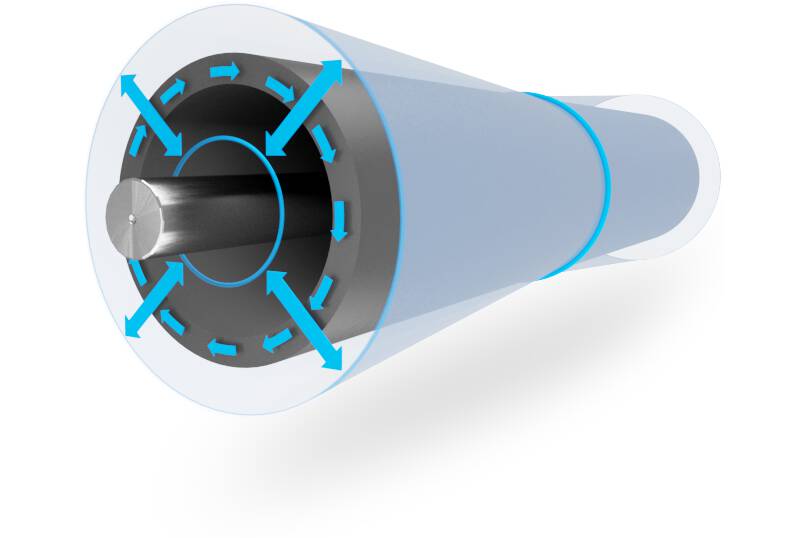

“What’s also notable, is the cylindrical shape and pivot bush that allow this belt tracker to swing and tilt during operation and to always be in full contact with the belt. Added to this, the Scrapetec PrimeTracker has the same peripheral speed over the entire surface of the belt, where traditional crowned rollers have different speeds at the center and edges of the system.”

Other advantages include easy installation, low maintenance requirements, and protection of belt edges and structure of the conveyor belt. A strong corrugated EPDM rubber hose protects this system from dust and sand, while the rubber pivot offers soft suspension of the tracker shaft, ensuring extended service life of the system. This system can be installed in front of every return pulley, above and below the belt. Perfect also in reversible operation.