Bishop’s cap, butternut, nutmeg or the popular Hokkaido: numerous variations of the colourful autumn vegetable are available in the fall. Unfortunately, however, pumpkin plants absorb organochlorine pesticides (OCPs), among other things, particularly easily from the soil as a result of earlier conventional cultivation.

In most cases, however, the residues in samples from the European region are well below the legal maximum levels nevertheless an examination of pumpkins mandatory.

In order to grind small amounts of the pumpkin sample to a fine powder, we equipped the laboratory mill with a stainless steel grinding set and a grinding ball with a diameter of 50 mm.

Grinding parameters:

- Feed quantity: 7 g

- Feed size: 12 cm diameter

- Grinding time: 1.5 min

- Final fineness: fine powder 150 µm

Test grinding

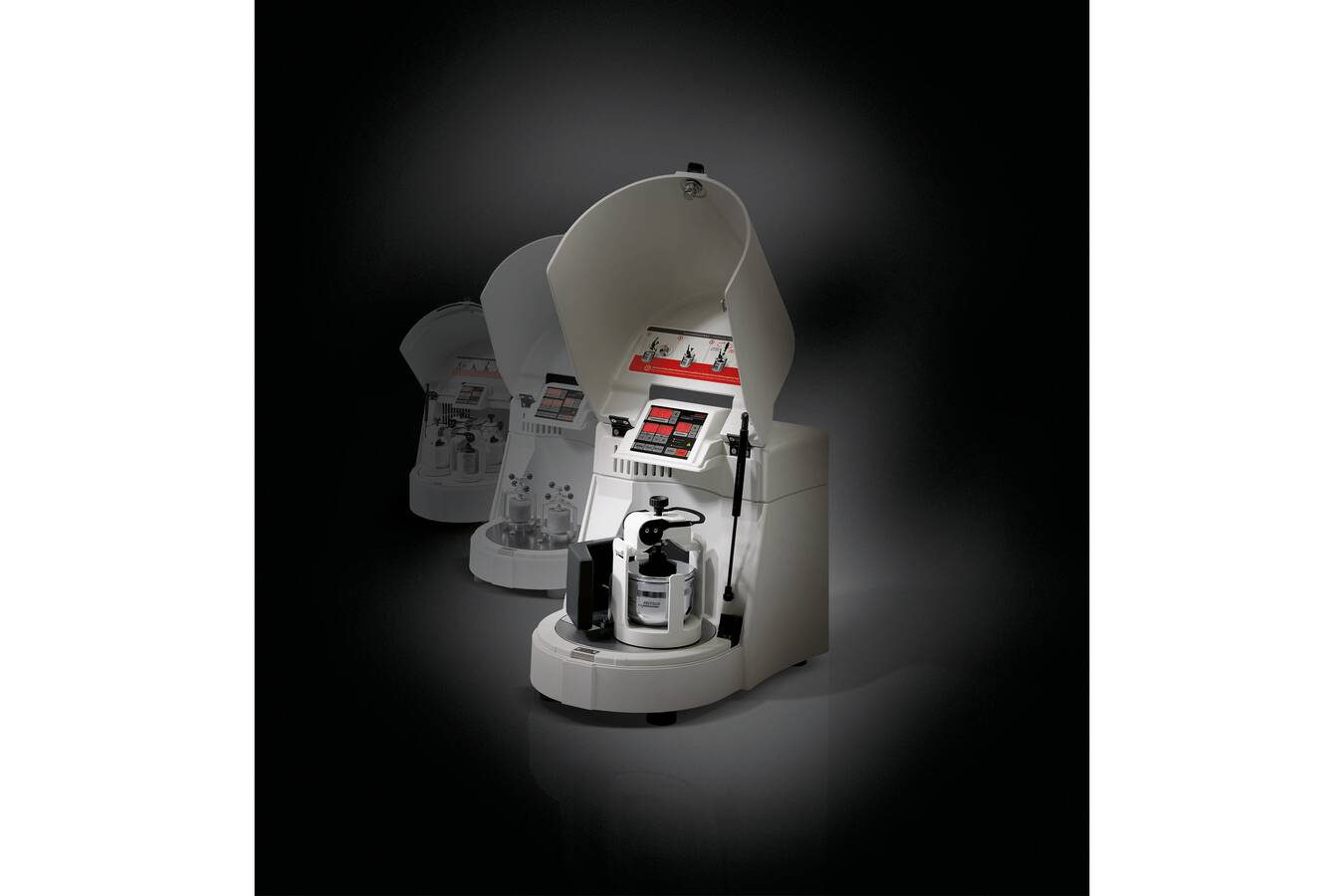

In this test we used our Vibratory Micro Mill PULVERISETTE 0 with cryo-box and stainless steel grinding set. An amplitude of 3.0 mm was pre-programmed. We used a few grams of the pre-cut pumpkin sample as a batch. Both the pre-cut sample and the grinding set were pre-brittle and/or cooled using nitrogen before grinding.

Pumpkin becomes powder

The sample was finally placed in the grinding set and ground at an amplitude of 3.0 mm with continuous addition of small portions of liquid nitrogen for 1.5 minutes.

The sample was ground to a fine powder, which became a paste again after evaporation of the liquid nitrogen. The grinding set was cleaned with hot water and a dishwashing detergent.

Conclusion

The cryogenic grinding of small pumpkin samples succeeds quickly and easily with the vibratory micro mill PULVERISETTE 0 and cryo attachment. The powder obtained can be used, among other things, for nutrient analysis or pesticide testing.