AZO GmbH + Co. KG

AZO - bulk material handling

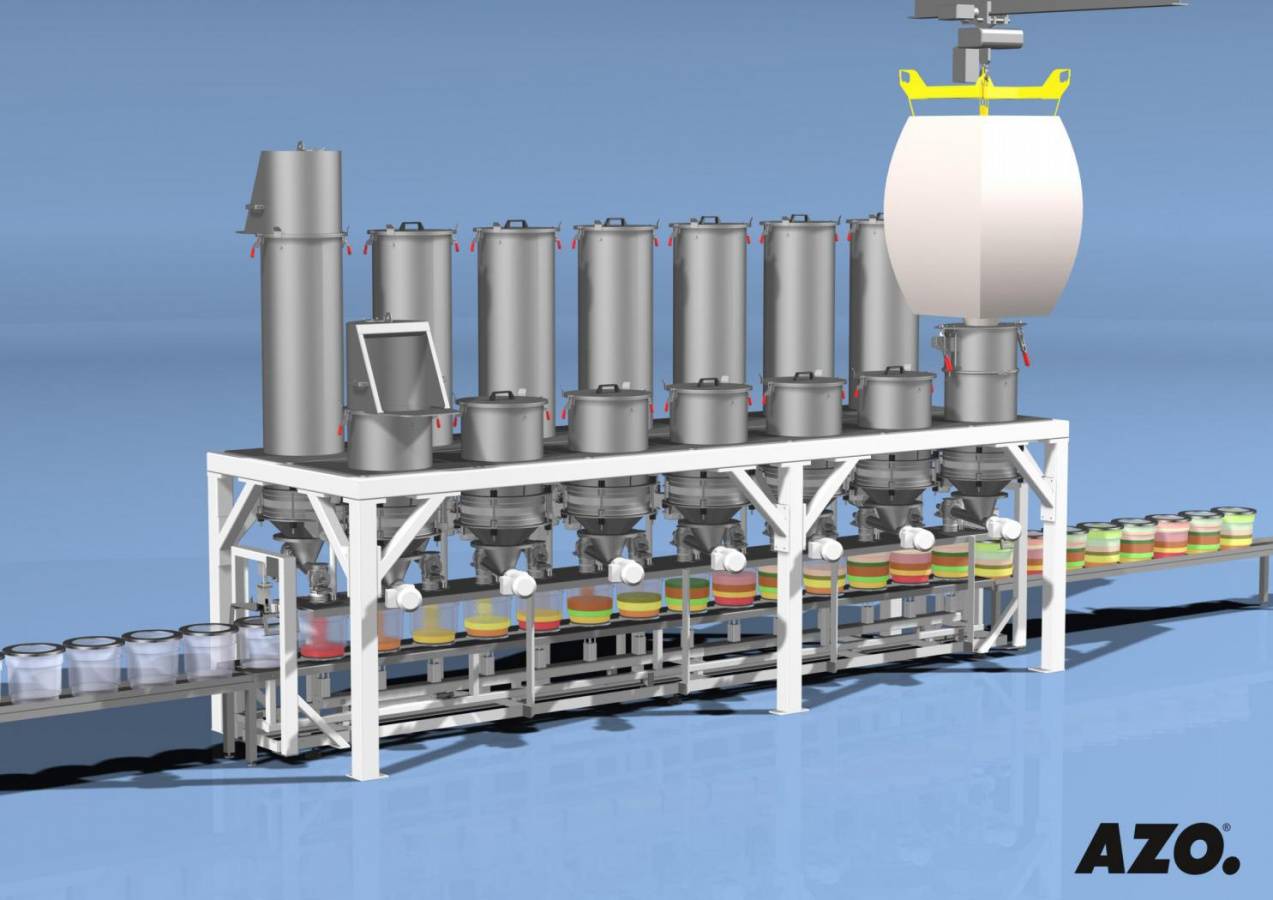

AZO provides innovative bulk material handling, raw material handling, pneumatic conveying systems, mixer feeding, screeners & bulk containers for the reliable automation of production processes for the industry in foodstuff, pharmaceutical, chemical and plastic.

You can also secure your prominent position with efficient, sustainable and energy-efficient automation concepts from the number one in mixer feeding: Made by AZO!

After Sales Service

In our After Sales Service department, we field a permanent team of skilled assembly supervisors who work all over the world with appropriate personnel to integrate our high-tech equipment reliably in factory buildings and existing production processes.

engineering & services

Our highly knowledgeable engineering team will help and support you; answering all of your questions about our services, engineering new plants, or modernising and making sustainable improvements to your existing production plants.