E & R B.V. 40 years of partnership with Netzsch and Winkworth

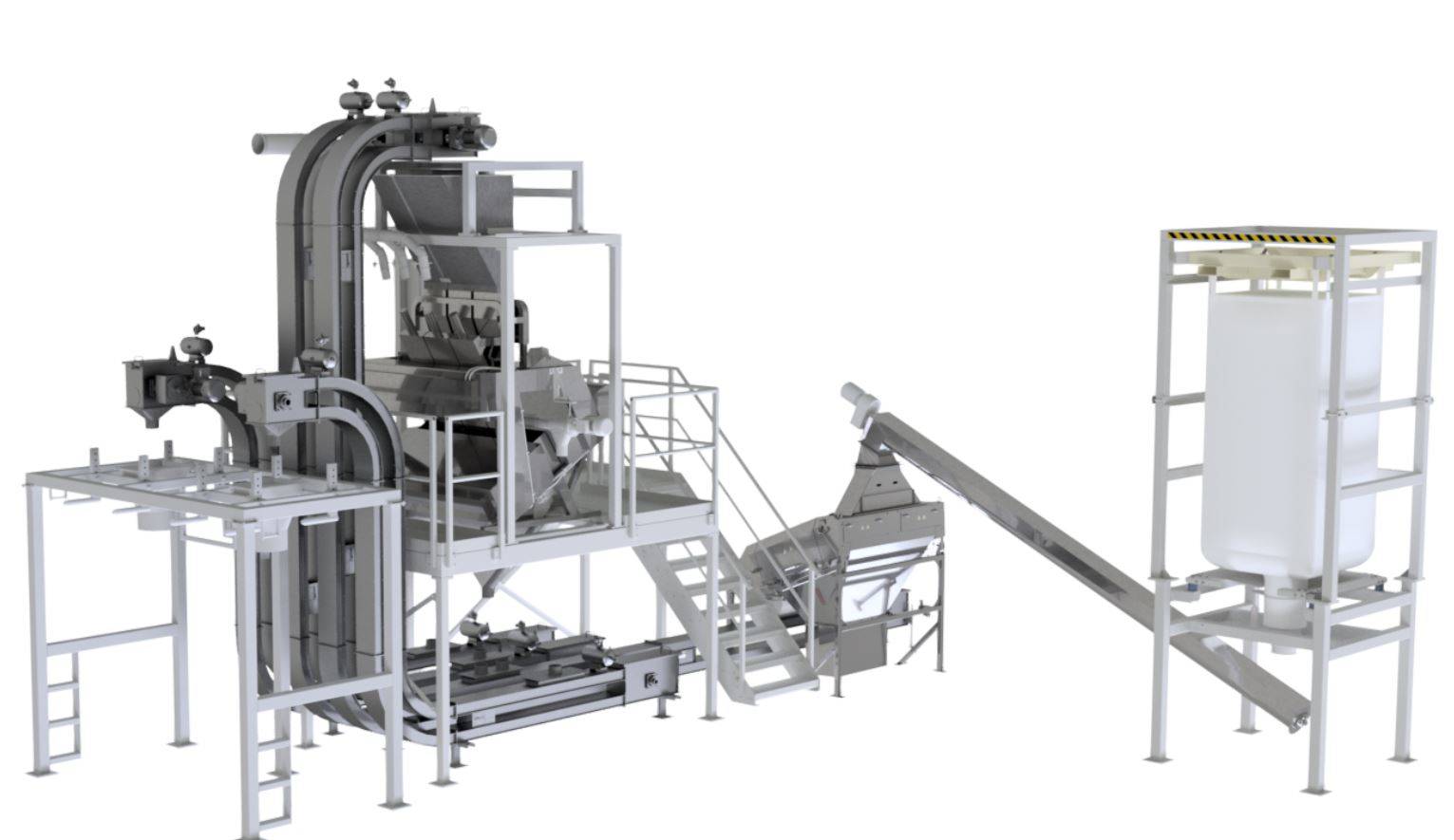

In 2020, E & R B.V. Vlaardingen will celebrate together with its partners from the first hour, the Netzsch Grinding & Dispersing Group from Selb (D) and the company Winkworth Mixers from Basingstoke (UK) 40 years of partnership in the Benelux.

A milestone for E & R and both partners for which E & R has been the exclusive agency in the Benelux since 1980. Over the years, the programs of both Netzsch and Winkworth grew strongly, due to acquisitions, specialization and program expansion.

Etienne Esseveld, director-owner of E & R: "We are proud and grateful for what we have achieved in the Benelux as an independent family business together with our foreign partners". Hundreds of mixing, dispersing, grinding, and kneading machines have been delivered and installed in the last 40 years, and the successful collaboration with our customers gives us a lot of energy and satisfaction”.

In the course of 2020 E & R B.V. will celebrate this 40-years of partnership through various