Customer-Specific Coatings and Core-Shell Particles

Targeted Surface Functionalization Are you looking for possibilities to produce powders that meet your specific requirements? Do you want to influence the surface structure and functionality of your particles?

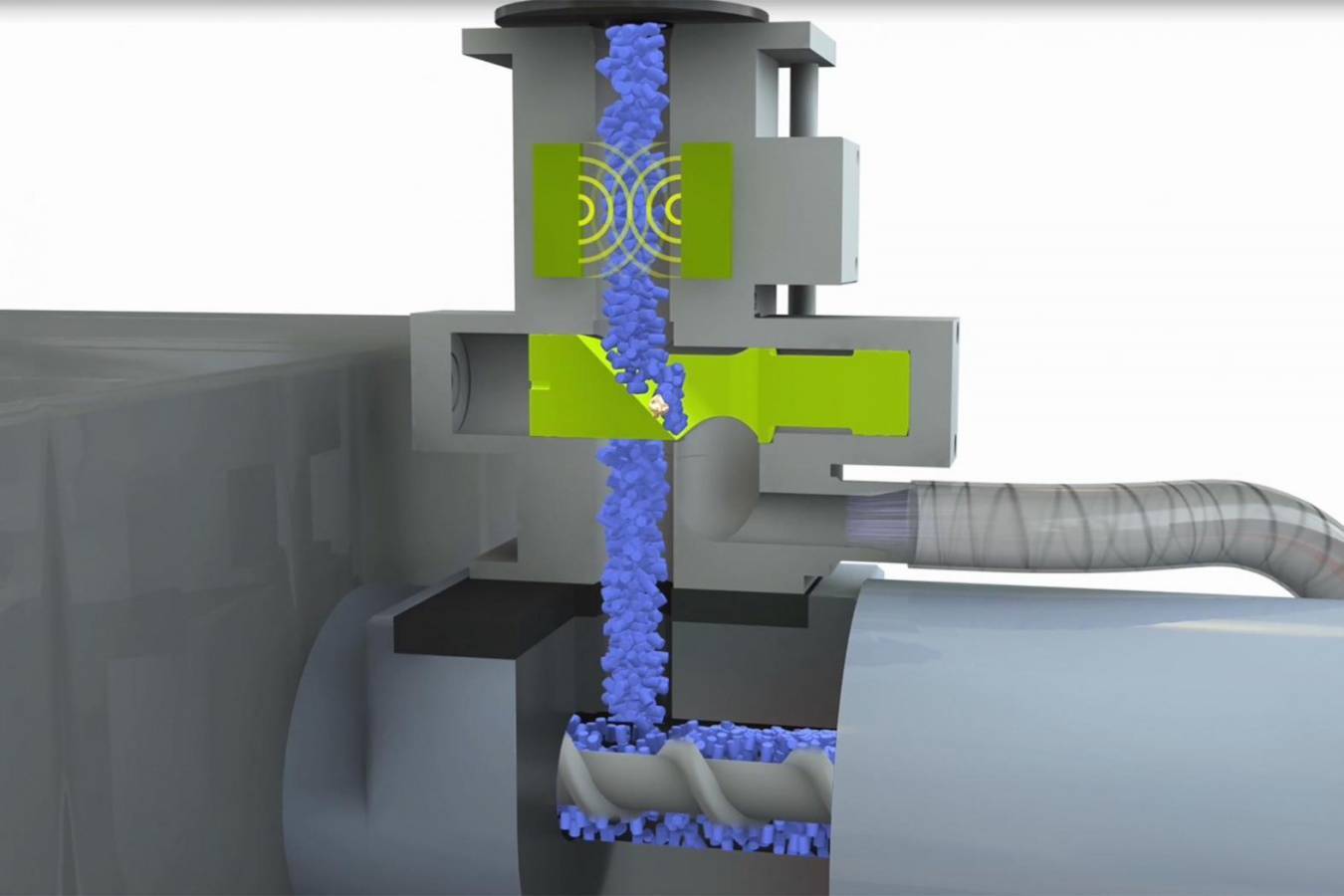

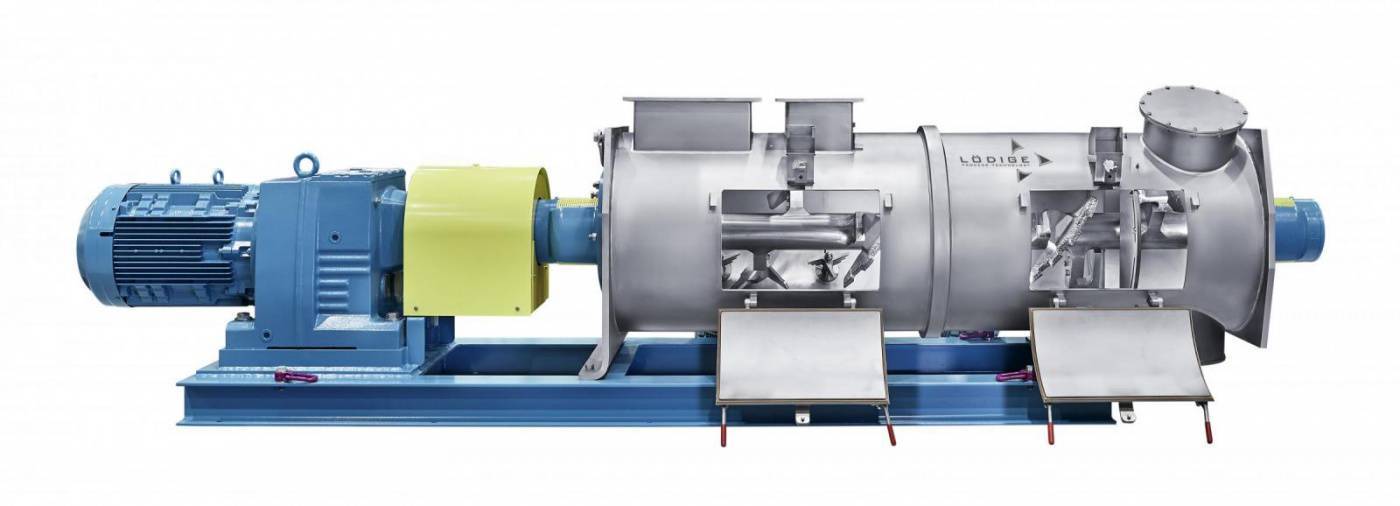

Using APPtec®, a unique spray calcination technology, it is possible to generate, coat and subsequently calcinate particles at temperatures from 200 °C to > 1000 °C in one single process step, thus producing so-called core shell particles. The technique enables coat thickness, porosity, and activity to be individually defined. By coating carrier materials, such as Al2O3, ZrO2, TiO2, with a catalytic ingredient, highly active powder materials for an extremely wide range of catalytic materials are obtained. Additionally, it is also possible to coat silicates, ceramic base materials and others with oxide coatings generated from metal salt solutions and slurries. Due to the extremely homogenous reaction conditions and short retention times by applying APPtec®, the coatings are extremely homogeneous