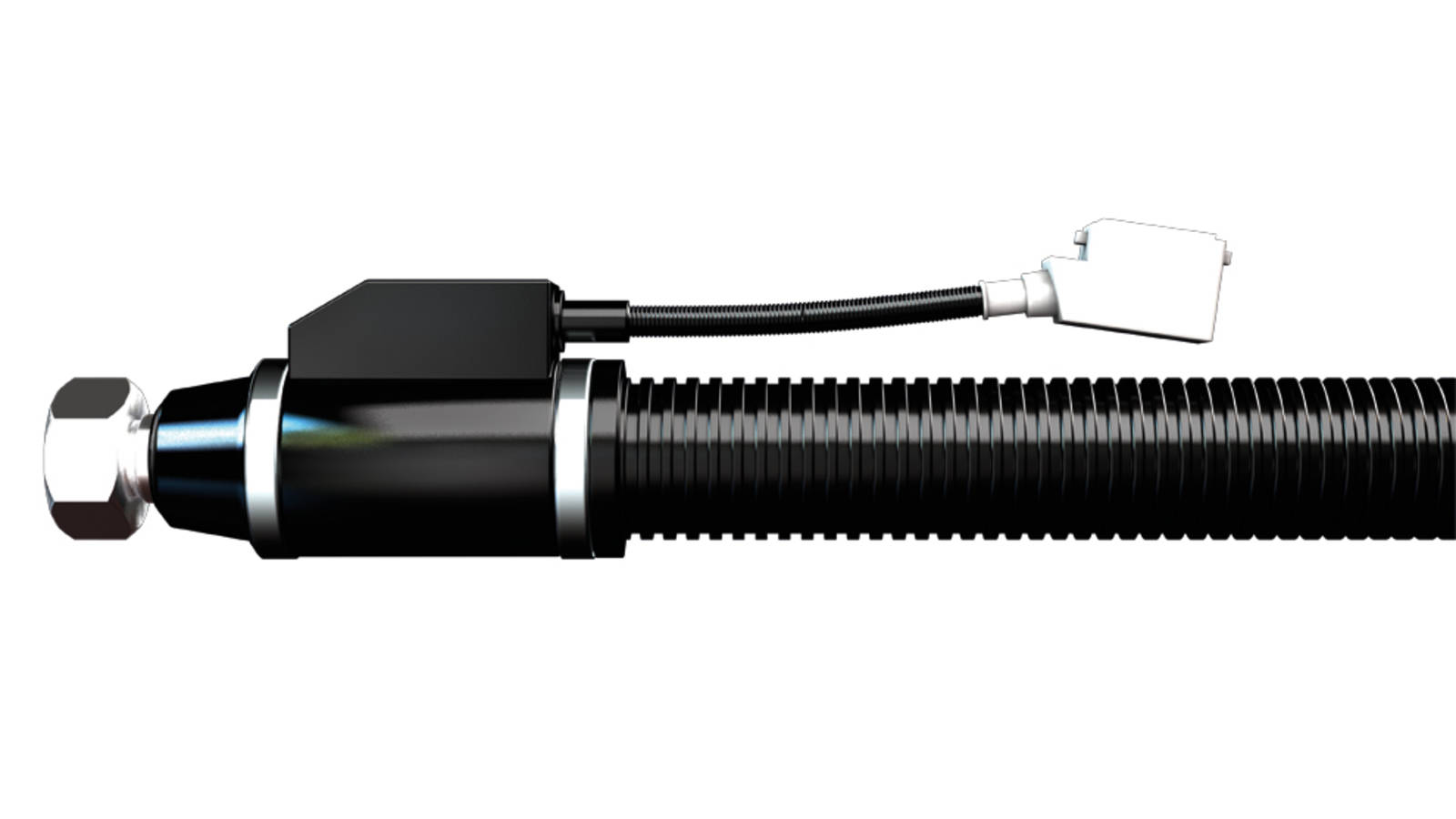

Heated Hoses

For heating or preventing heat loss Electrical heated hoses (heated sample lines) are the ideal solution for flexible transportation of liquid or gas substances without heat loss. The necessary temperature, power, application and outer protection material determine the choice of the heated hose technique.

Avoid freezing of gases

Gas substances are channeled from the measurement point to the analysis instrument in the analysis technique, i.e. in trash burning ovens, refineries, chemical industry, motor exhaust analysis, etc.. For these applications the gases are to be freeze protected, protected against condensation, or guarantee for constant temperatures up to 250°C. Heated sample lines (analytic hoses) ensure the transport of liquid and gaseous media without the loss of temperature.

Keep liquids liquid

Moreover, a heated hose can be used to heat up, to prevent heat loss and to transport media, e.g. grease, oils, wax, resins, bitumen, varnish, water, carbon dioxide, foam plastics, casting compounds,