Autumn Training at UWT every Year

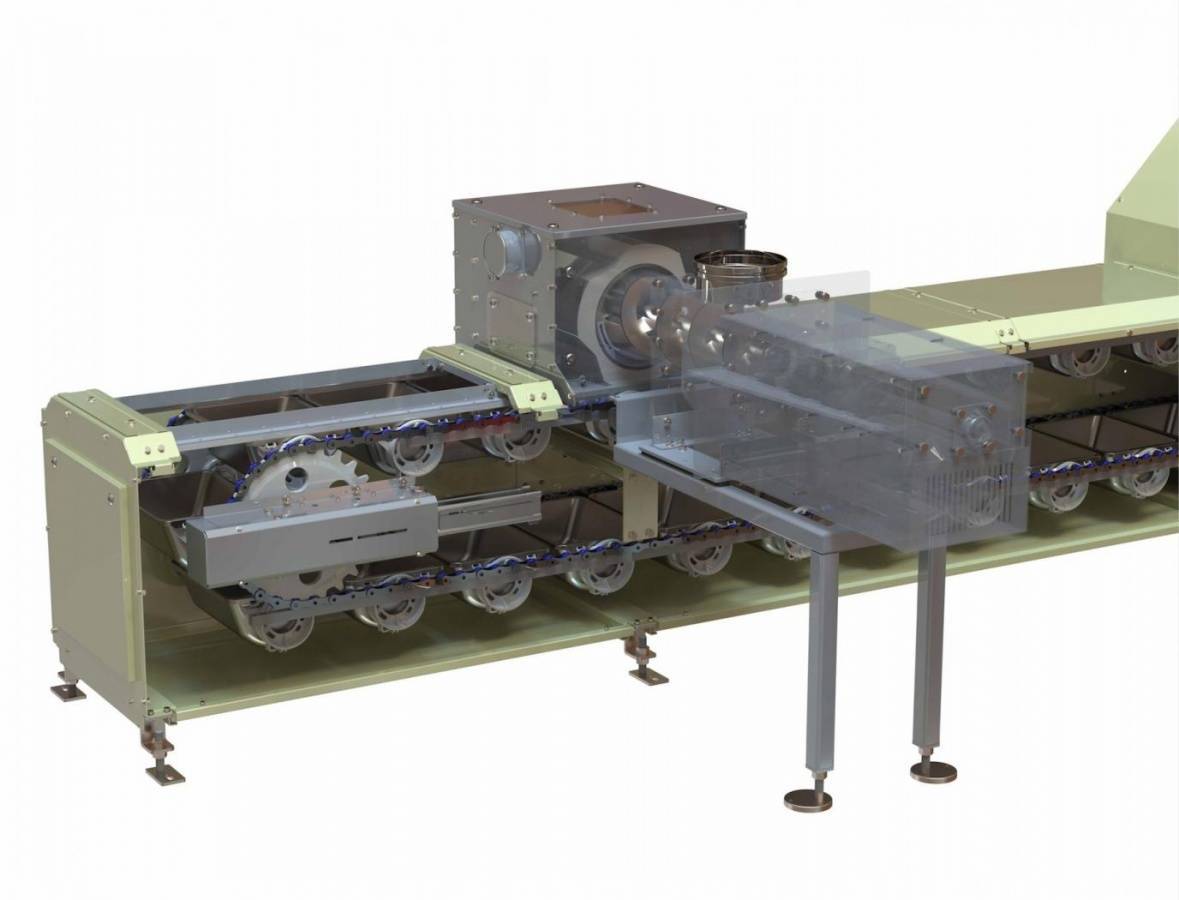

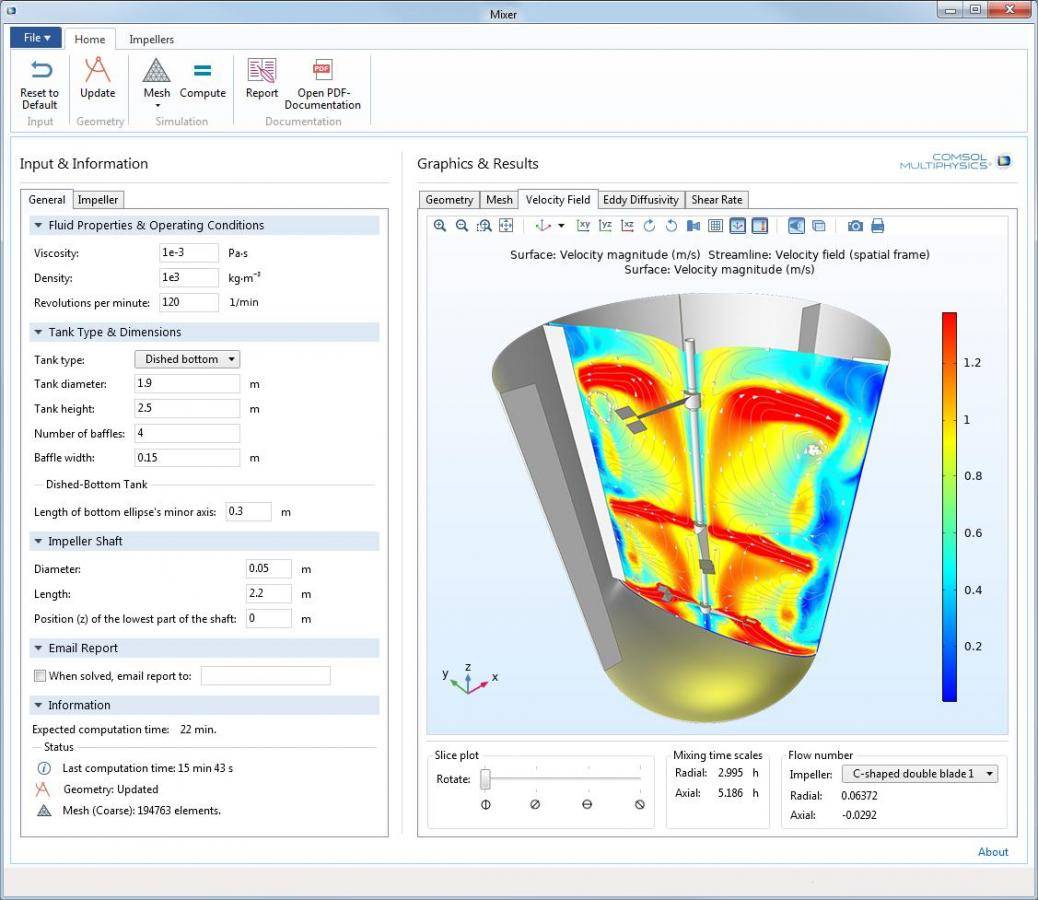

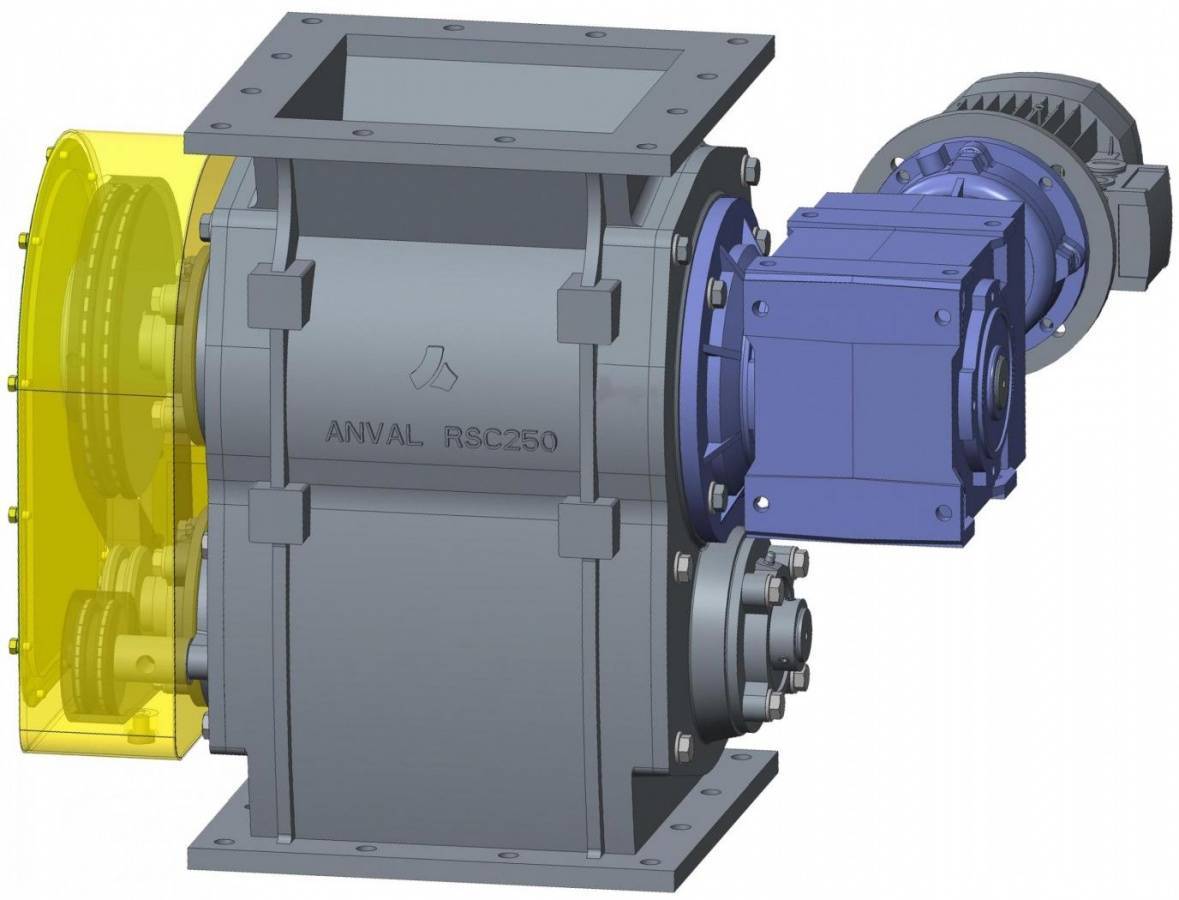

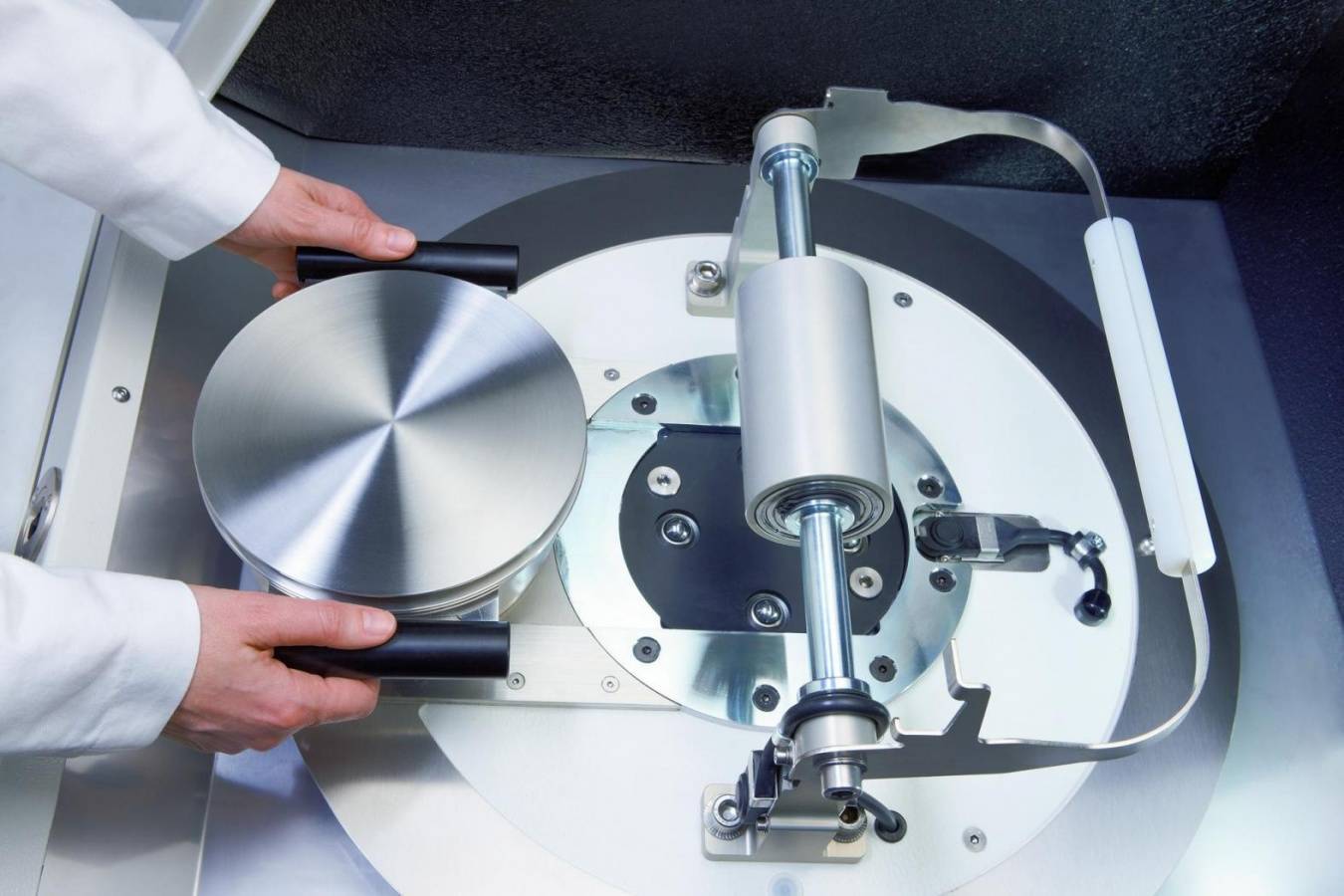

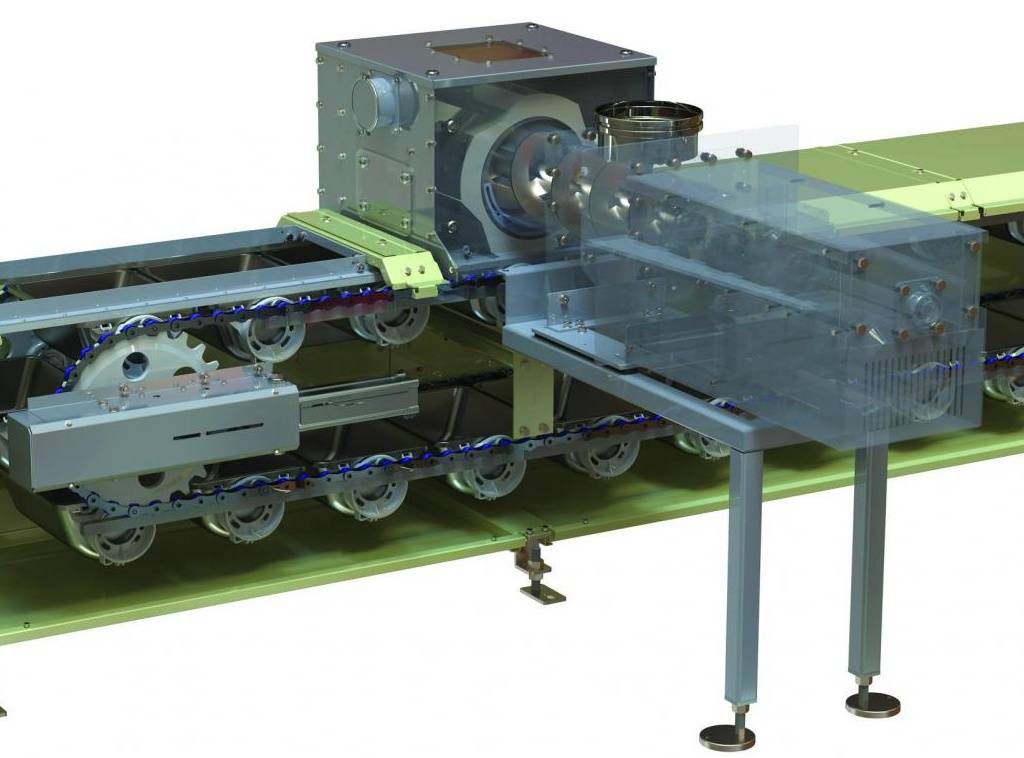

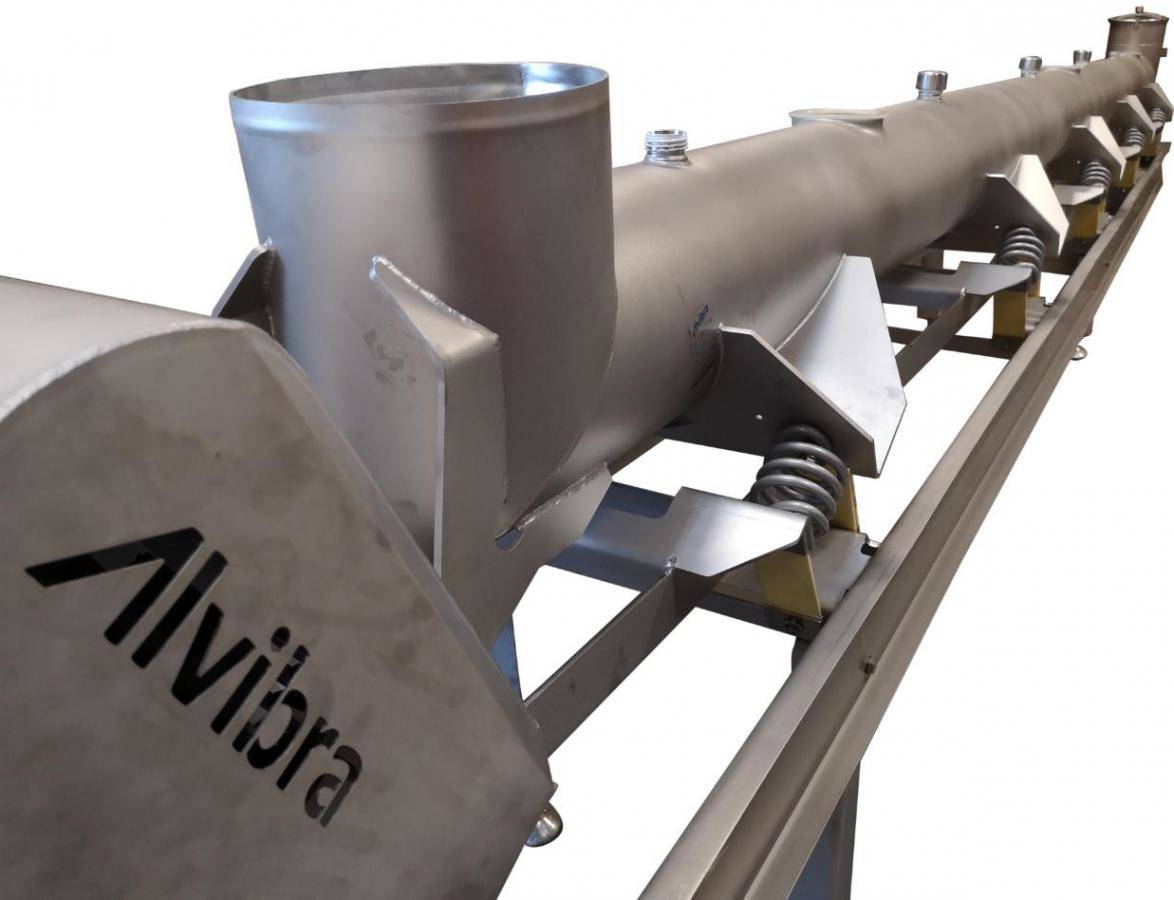

40 Participants from all over the world took part at this event Markus Schalk welcomes the participants , Introducing the new capacitance sensors from UWT, UWT Export Team is glad having 42 nations taking part, New exhibition unit from UWT, New Portfolio will be presented, UWT welcomes 40 participants from all over the world, Alina and Camille are part of the export team at UWT, Proud Dad, Participants of the autumn Training 2018, One of a bowling winning team, After work bowling event, Traditional location for the bavarian event, Bavarian Sound by UWT members, Familiy is part of the bavarian event, Bavarian clothes for Don Crader UWT LLC. USA, Happy people from 42 countries, Camille, Britta and Julan from UWT welcomes the guests, A big thank you to all our guests