Vacuum Conveying – Necessary Evil or Process Champion?

Introduction

Vacuum conveying or pneumatic transfer is often regarded as a necessary evil in processing. Why spend money on a system which does not alter the process or add value?

The truth about vacuum conveying is quite the opposite, and a well-designed system can enhance a process, increasing throughput and efficiency, eliminating the risk of operator injury and exposure, and ensuring product containment.

The Problem

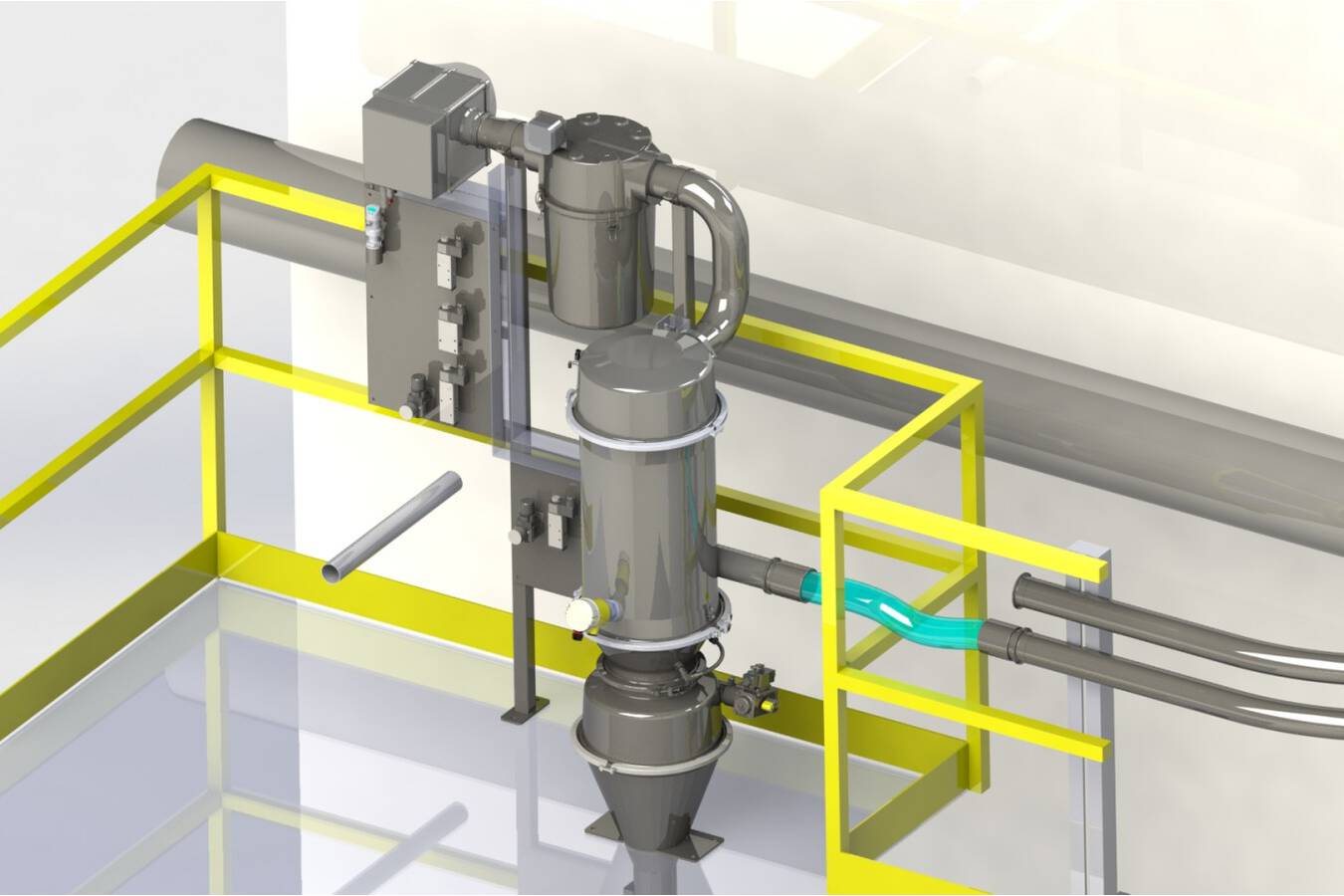

The typical integrated pharmaceutical granulation suite is perhaps the best example of these principles being optimally applied.

The raw material is first loaded into a high-shear mixer / granulator. The dried granule is then passed through a second mill to remove agglomerates formed in the drying process, and then into bins or IBCs for onward movement to tabletting etc.

The movement of the wet mass from high-shear mixer, through the wet mill and into the dryer bowl is most commonly achieved under gravity, but it is