1 million times successfully solved level detection

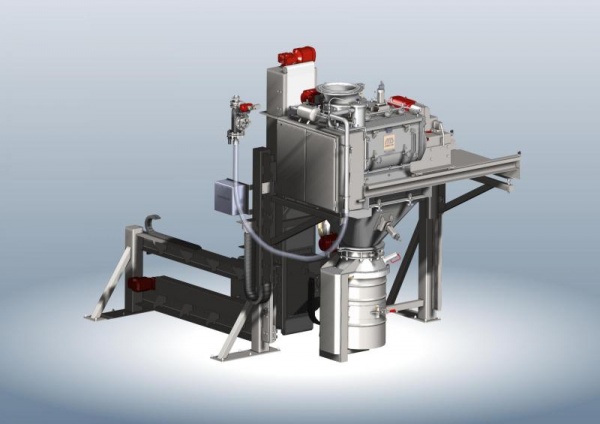

With the right attitude and a great team, anything is possible The UWT GmbH has become one of the world leading manufacturers of measurement technology for the detection of content and level limit in any kind of bulk materials and solids. Different measurement methods in storage silos, containers or tanks are installed to monitor their content and control it. Applications can be found in food, plastics, wood, rubber, environmental plants and power stations as well as the building materials and chemical industry. Headquarters, development and production facilities are located in Betzigau. Besides UWT is represented in more than 50 countries worldwide and has own sales offices in the US, UK, in China and India.

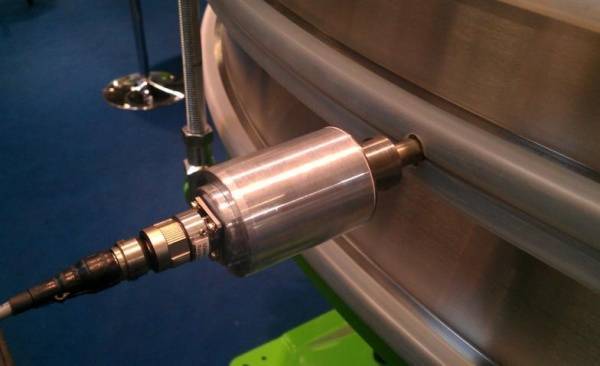

End of August 2015, it happened: the installation of an RF detector for a considerable cement and lime producer, the 1,000,000th application has been successfully implemented.

The RF sensor is the new capacitive level switch of UWT. For the anniversary application the single rod probe was installed as tailback detector