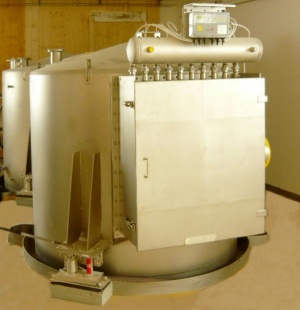

Filter units for building materials industry

15 filter plants de-dust 26 dust sources Beside the big coal and natural gas reserves, Siberia also disposes of an immense potential in lime and marl stone sources. The mineral resources are required as raw material base for the cement production. Because of the Russian „programme for the development of building material industry till 2020“ and the rising demand for cement and chemical construction products, increase the extension of the building material industry. So also in Nowosibirsk. There the company Gerkules-Sibir was founded in 1997. The building material supplier produces the raw materials of the cement industry to dry mortar, gypsum plaster, screed etc.

In 2013 Gerkules modernised its plant 7 and refurbished also the de-dusting units. The order of 15 filter units for de-dusting of 26 dust sources (elevators, crusher, sieves, scale bunker, belt transfer points, packing machines, pneumatic conveying etc.) was awarded to SovPlym, the Russian representative of Infastaub.

Overall the 15 filter units