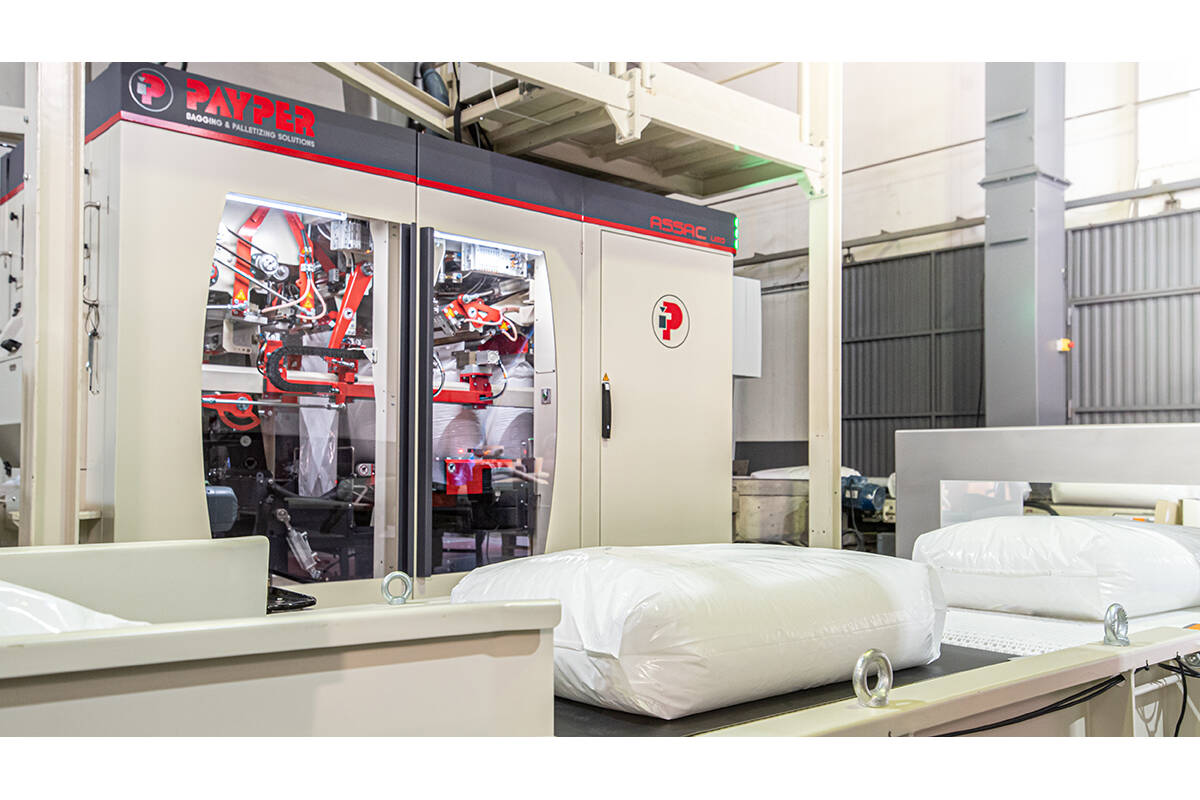

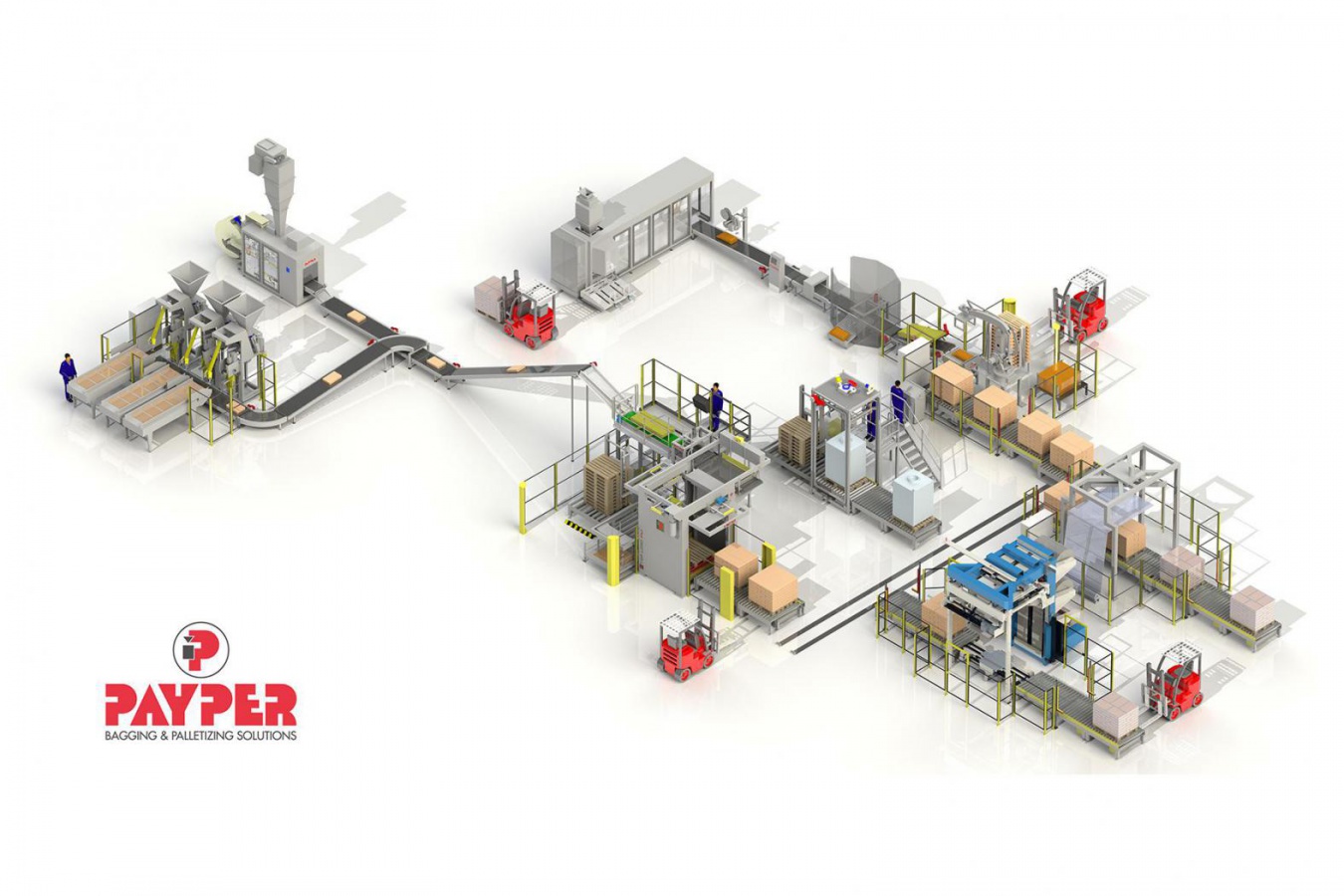

Next-generation packaging lines for bulk solids.

PAYPER was established in Spain in 1973 and we have specialised in the design and manufacturing of machinery for dosing, weighing, bagging, palletizing and overwrapping solutions.

At the service of your industry: we put our experience, technology and knowledge at the service of industries as diverse as mining, building, petrochemical, chemical, fertilisers, feed and food.

Our clients endorse us: more than 4,000 projects with PAYPER technology installed in 75+ countries in the world.

8 subsidiaries and an extensive agent network constitute our efficient sales- and service organization worldwide, ready to solve any query from our clients.