Woven wire cloth, filter cloth, screen sections, round frames, re-screening service, aeration elements, filter elements and fabricated parts, test sieves, test sieve shakers, photo optical particle analyser, bagging machines for all types of bulk goods, screening plants for dry and wet screening, high pressure washing units.

Products, services

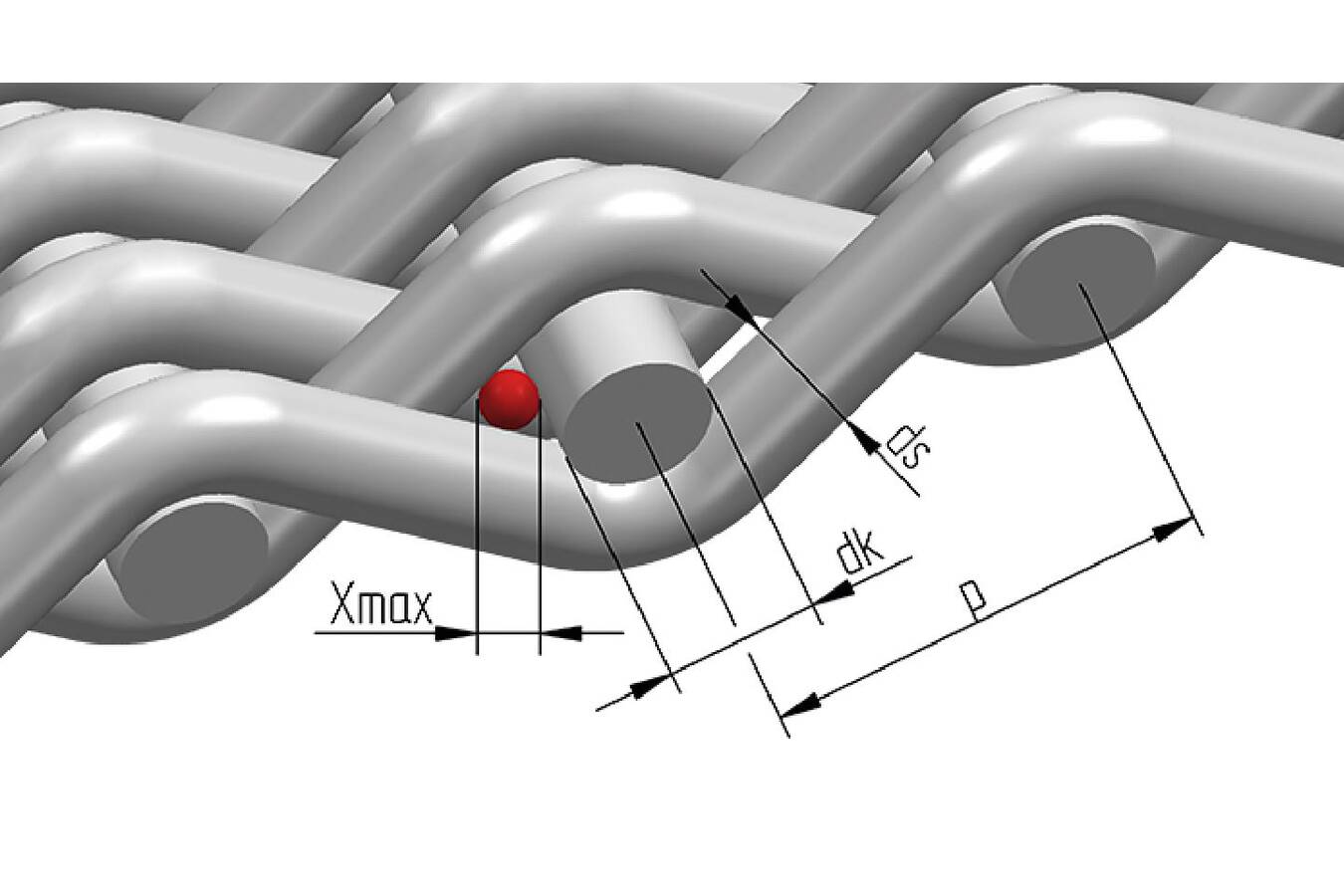

Metal gauze - woven wire cloth, screens, metal wire cloth, metal filter cloth

Particle anylysis - test sieves, test sieve shaker, photo-optical particle analyser for particle size and particle shape analysis 0.025 - 400 mm

Particle size analysis - test sieves, test sieve shaker, photo-optical particle analyser for particle size and particle shape analysis 0.025 - 400 mm

Air jet sieves - test sieves

Sieves - woven wire cloth, metal wire cloth, screens, metal filter cloth, filter elements, fabricated parts

Vibrating sieves - industrial wire screens, round screens, screen frames, re-screening service

Vibrating sieve machines - test sieve shaker

Aeration bottoms - plymesh aeration pads

Laboratory sieves - test sieves, grid sieves, test sieves for cereals

In-process measurements - photo-optical online particle analyser for particle size and particle shape analysis 0.025 - 400 mm

Categories

Storage - Silo discharge -

Aerated bottom for silo dischargeSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Backwash filtersSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Bag filtersSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Basket filtersSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Candle filters

Show more

Categories

Storage - Silo discharge -

Aerated bottom for silo dischargeSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Backwash filtersSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Bag filtersSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Basket filtersSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Candle filtersSeparation, sieving, filtering - Sieving, sieves -

Control sievesSeparation, sieving, filtering - Sieving, sieves -

Disc sievesSeparation, sieving, filtering - Sieving, sieves -

Drum sievesSeparation, sieving, filtering - Dedusting - Components, accessories -

Filters, filter materialsSeparation, sieving, filtering - Sieving, sieves -

Flat screensStorage - Components, accessories -

Flow promotion devicesPackaging -

Packaging in drumsPackaging -

Packaging in, filling of bags, sacksServices - Measurement, analyses -

Particle shape analysisServices - Measurement, analyses -

Particle size distribution measurementsSeparation, sieving, filtering - Sieving, sieves -

Rotary sievesSeparation, sieving, filtering - Sieving, sieves -

Shake sievesSeparation, sieving, filtering - Centrifuging, filtering -

Sieve bendsSeparation, sieving, filtering - Centrifuging, filtering - Filters - filtering equipment -

Tube filtersSeparation, sieving, filtering - Sieving, sieves -

Vibratory sieves