Innovative solutions for conveyor belt problems at GEAPS Exchange

”Scrapetec made a successful debut at GEAPS Exchange 2024, the largest grain handling event, where they presented innovative products to address common conveyor belt challenges. The company’s participation resulted in numerous future projects.”

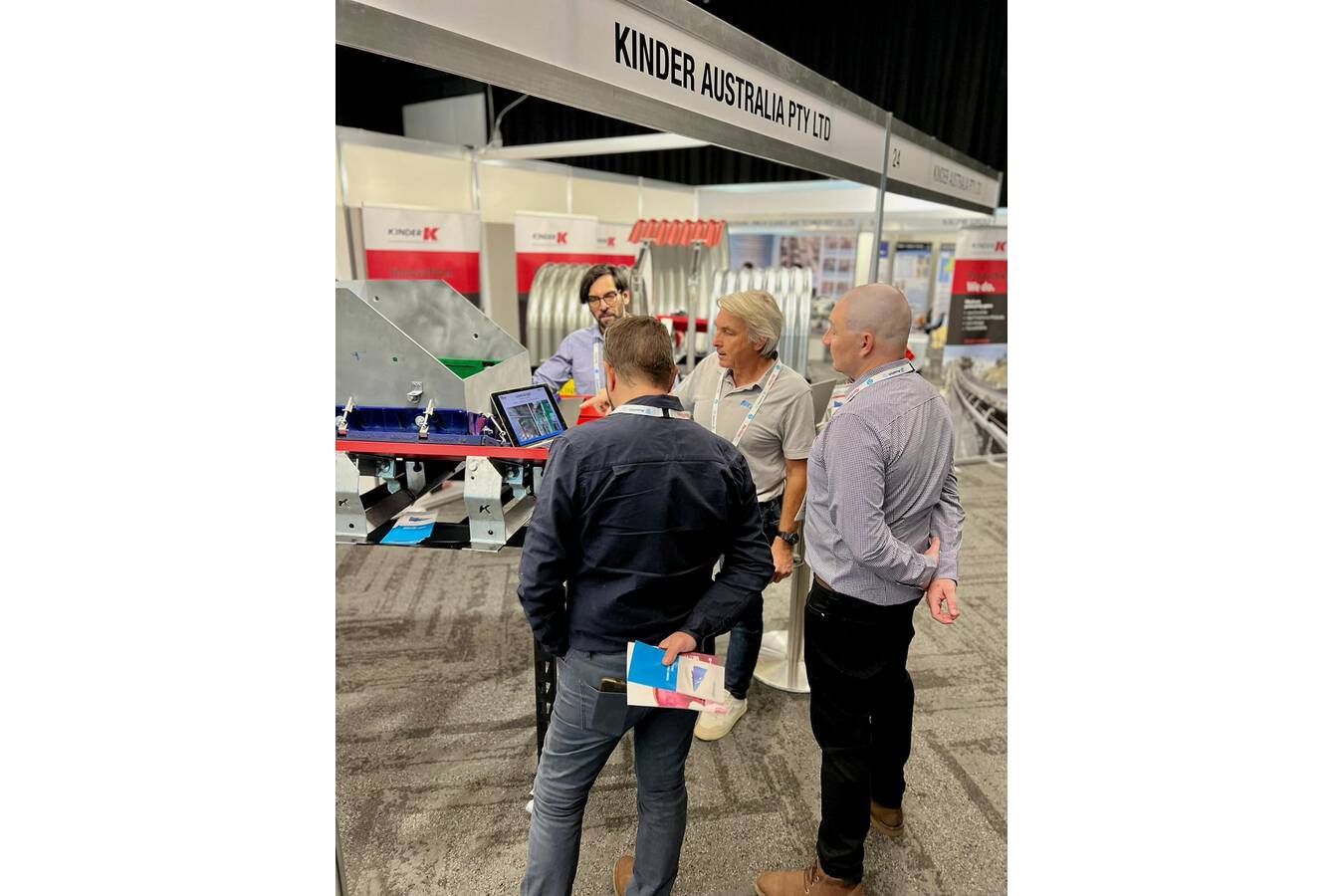

The GEAPS Exchange 2024 in Denver was the global center for grain handling this year. This trade fair, the largest and best of its kind worldwide, was attended by 3700 visitors and 1000 companies from a total of 23 nations. A total of 391 exhibitors presented their latest and most innovative products and services. The program was complemented by more than 45 hours of interesting and informative education on the subject of grain handling. One of the exhibitors at this impressive fair was Scrapetec. And it was not just any appearance - it was the company’s first dedicated booth at this important global platform and the debut could not have been better. Together with their partner BLT World, they presented their innovative products and were literally stormed. The response and interest were tremendous. In fact, the brochures, business cards and samples were exhausted on the last day and the team’s voices were hoarse from all the talks and presentations. It was an undeniable proof of the strong interest of the industry in the solutions and products of Scrapetec. Products that solve the well.known problems such as dust, spillage and excessive maintenance at the conveyor belt transfer points in a new way. The participation in the GEAPS Exchange was a complete success for Scrapetec. Now it is necessary to make the numerous projects that have emerged at the fair a success. But the Scrapetec team is motivated and looks confidently into the future. The next GEAPS Exchange can come - Scrapetec will definitely be there again and show its innovative products for the conveyor systems or conveyor belt transfer points. We are already looking forward to this exciting event next year. Together with companies like Scrapetec, the GEAPS Exchange remains the most important fair in the field of grain handling. The success of Scrapetec is an inspiring example of what commitment, creativity and technological innovation can achieve in our industry.